- English

- Japanese

- TEL

- 81-78-335-7573

SEARCH

Blade

- Models

- Overview

-

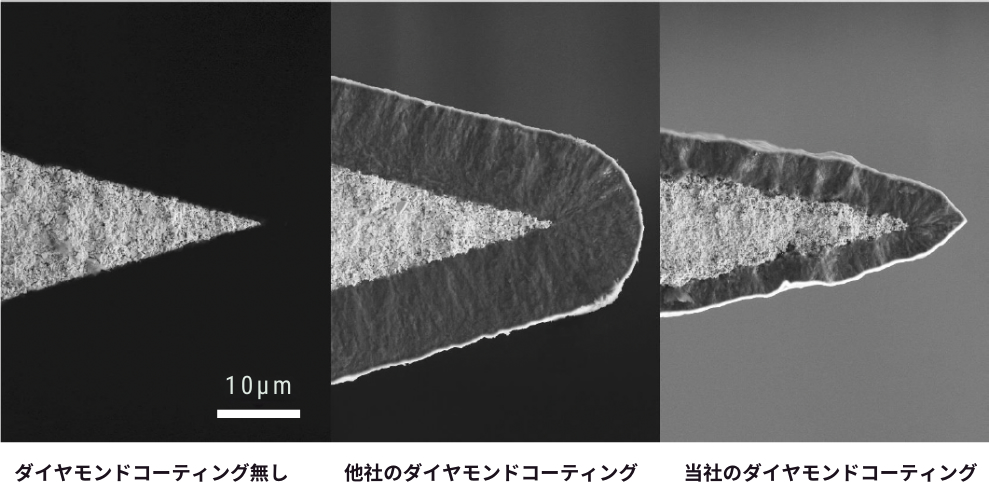

GFD's diamond Foil Blade are celebrated for their exceptional wear resistance and razor-sharp precision, effortlessly meeting the most stringent requirements.

Manufactured under the name Diamaze PSD (Plasma Sharpened Diamond), these diamond-coated carbide blades are purpose-built for applications demanding extreme wear resistance.

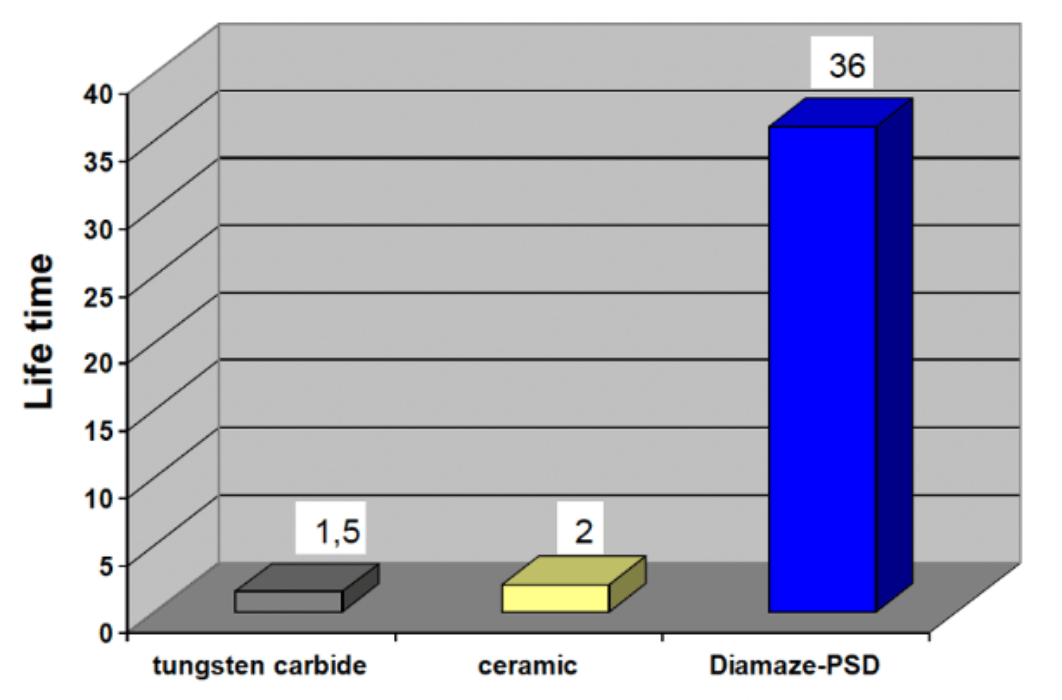

Capitalizing on the remarkable hardness of diamond, Diamaze PSD blades boast service lives up to 1000 times longer than conventional steel blades and up to 20~60 times longer than carbide and ceramic alternatives.

Leveraging advanced plasma polish technology, GFD ensures that Diamaze PSD blades maintain exceptionally high sharpness, guaranteeing precise cutting performance with minimal maintenance requirements. This not only saves time but also reduces associated costs.

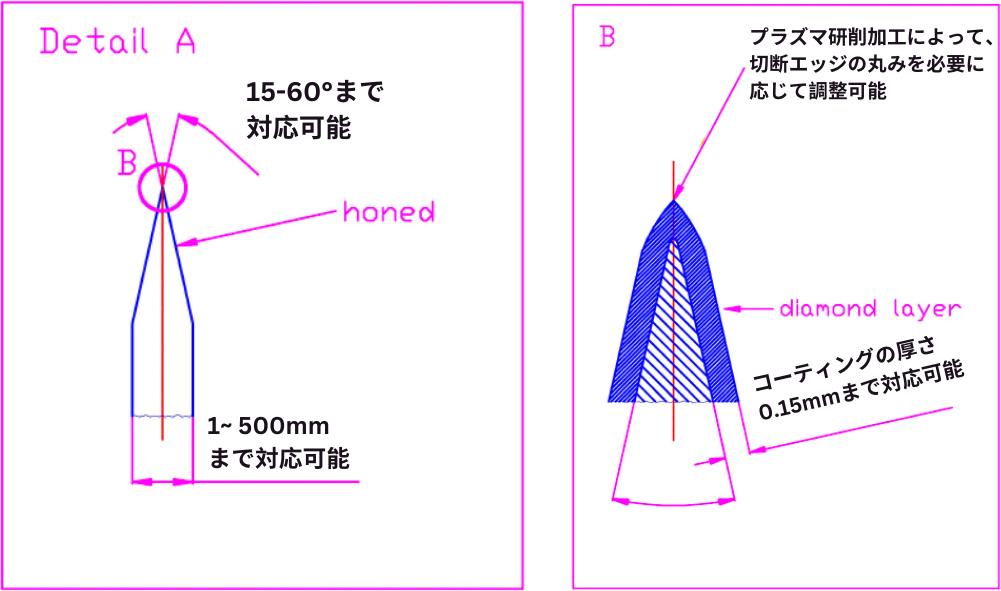

Sharpenable cutting angle 15°- 60°

Length and width of the blade 1 mm – 500 mm

Minimum blade thickness approx. 150 µm

Single-sided and double-sided ground cutting edges can be produced

Sharpening process is self-adjusting and can therefore also machine extremely complex cutting edge geometries

Intensity of the sharpening process can be freely adjusted

The plasma sharpening process allows the rounding radius of the cutting edge to be adjusted as required

Materials

BSF (Battery Separator Foil)

Aluminum foil

Copper foil

Metal foils

Plastic films

Paper, cardboard

Composite materials

Wood

Fabrics

Leather

Carbon fibers

Kevlar

Areas

Battery industry

Films and fiber industry

Pharmacy and medical technology

GFRP and CFRP in the aerospace industry

Textile and paper industry

Packaging industry

Customers have the flexibility to specify the shape of the cutting blades or collaborate with GFD. With extensive experience in developing cutting solutions, GFD ensures that the blades are tailored to meet the customer's specific needs and requirements.

The following is a comparison of the lifespan between Diamaze PSD blades and ceramic blades when cutting plastic film containing pigments (titanium oxides).

Models

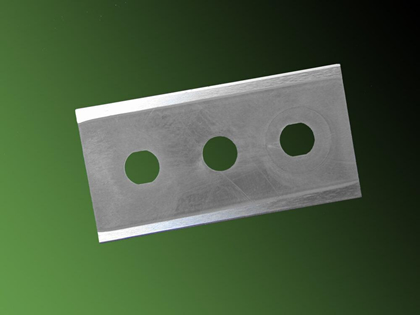

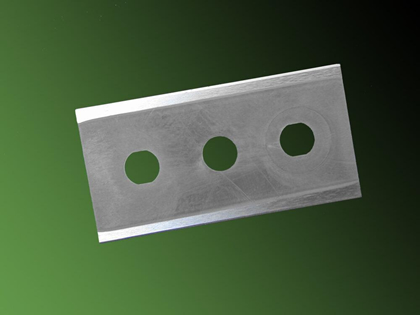

Diamaze PSD foil blades (3 holes)

Diamaze PSD foil blades (3 holes)

| Code | Size |

|---|---|

| K.0020.020 | 43mm x 22mm x 0.2mm DOUBLE |

| K.0020.021 | 43mm x 22mm x 0.2mm SINGLE |

| K.0020.030 | 43mm x 22mm x 0.3mm DOUBLE |

| K.0020.031 | 43mm x 22mm x 0.3mm SINGLE |

| K.0020.040 | 43mm x 22mm x 0.4mm DOUBLE |

| K.0020.041 | 43mm x 22mm x 0.4mm SINGLE |

| K.0020.060 | 43mm x 22mm x 0.6mm DOUBLE |

| K.0020.061 | 43mm x 22mm x 0.6mm SINGLE |

Diamaze PSD foil blades (slotted hole)

Diamaze PSD foil blades (slotted hole)

| Code | Size |

|---|---|

| K.0030.038 | 57.5mm x 19.0mm x 0.2mm DOUBLE |

| K.0030.039 | 57.5mm x 19.0mm x 0.2mm SINGLE |

| K.0030.060 | 57.5mm x 19.0mm x 0.3mm DOUBLE |

| K.0030.061 | 57.5mm x 19.0mm x 0.3mm SINGLE |

Please feel free to reach out to Seibu Shoko for any inquiries regarding wear-resistant blades

1.Specialized Support

Seibu Shoko serves as the contact point for GFD Corporation in Japan and listens to your requirements. Please entrust us with the design and manufacturing of custom-made diamond-coated products not available in the Japanese market.

2.Dedicated Service Engineers

We have over 50 service engineers, including those from partner companies, on our team. We can also provide support for testing GFD Corporation's diamond-coated tools and blades.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.