- English

- Japanese

- TEL

- 81-78-335-7573

Generating Gear Grinding Machines

- Models

- Overview

-

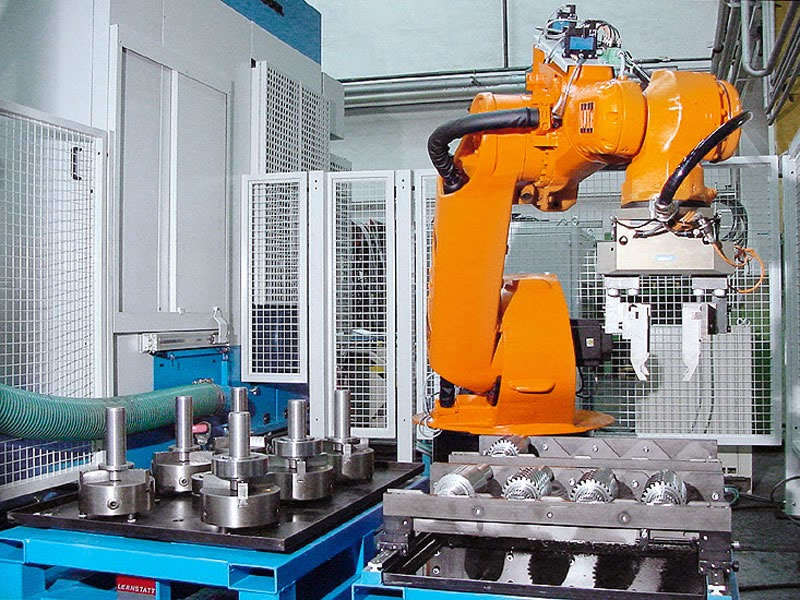

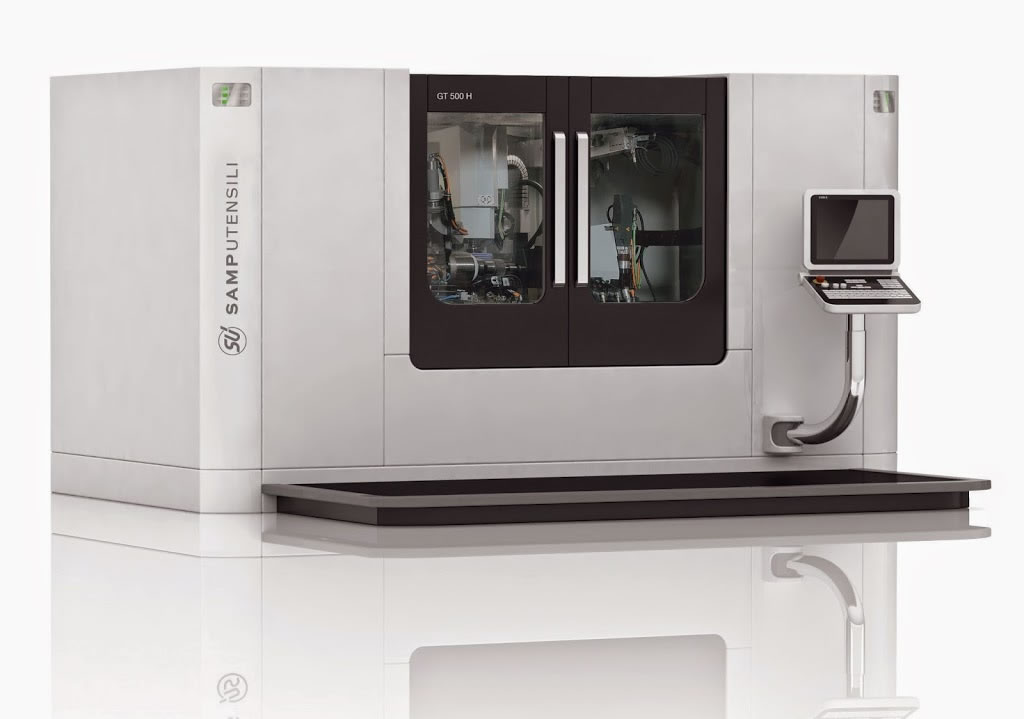

The Samputensili GT 500 H combines all profile and continuous generating grinding processes with the most avant-garde tooling technology around and can grind both complex gear geometries to perfection or mass produce your product when necessary, meaning that you are always ready to meet the needs of your own customers, both today and in the future.

The Samputensili G 250 / G 450, an absolute must for the production of gears up to a workpiece diameter of 450 mm. Simple design concepts in terms of tooling and dressing technology, fast automation and user-friendliness are the strengths behind this innovative machine. Dressing and profile grinding options are also available for the G 450, although not in such a vast range as with the GT 500 H. Moreover, by combining an G 250 / G 450 with one of our H series of hobbing machines, maintenance

becomes ‘child’s play, assuring top-level productivity at all times, while also allowing you a certain amount of flexibility.

Models

SG 160 SKYGRIND - Dry Grinding Machine

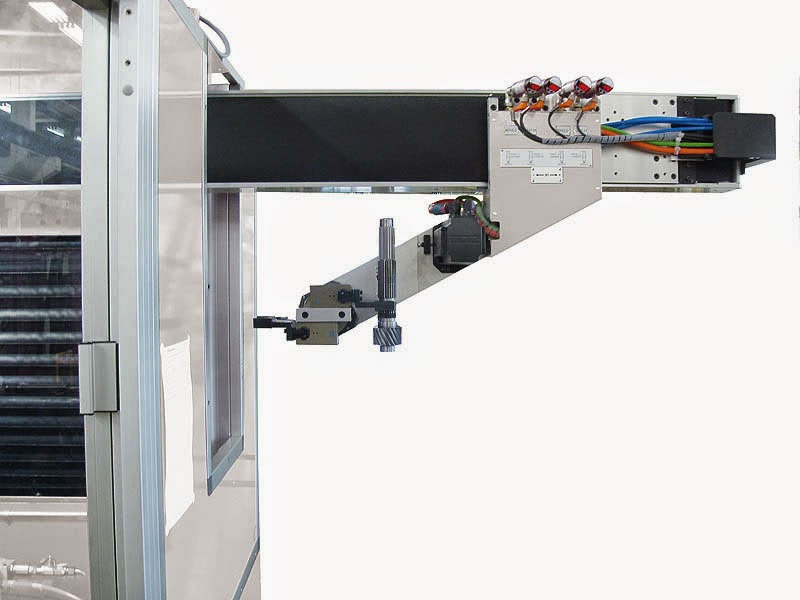

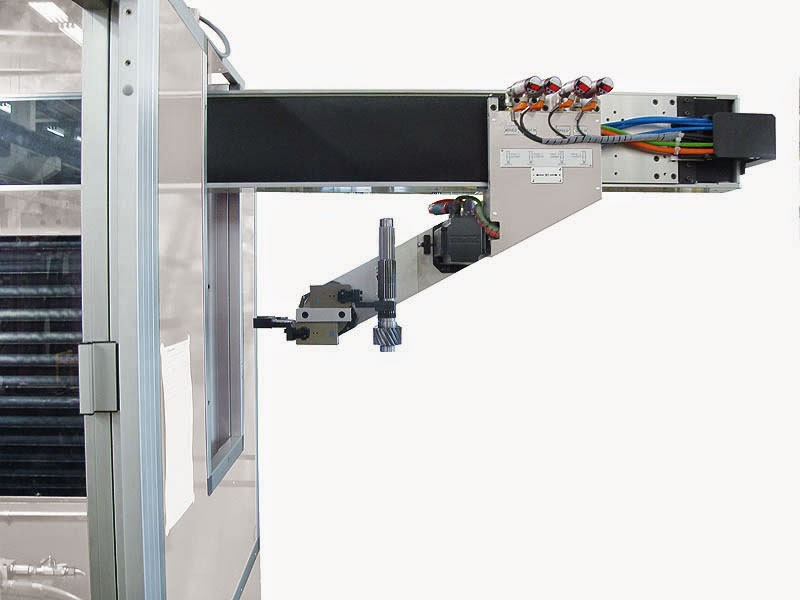

The SG 160 SKYGRIND is the world’s first gear dry grinding machine. This state of the art process removes the need for cooling oils during the hard finish grinding of the gear after the heat treatment. Roughly, 90% of the stock allowance in the first pass, using a hobbing tool is removed and subsequently in the second pass, a grinding wheel removes the remaining stock without causing problems of overheating the workpiece, which results in a fully dry process. The innovative structure with two spindles actuated by the linear motors and the use of more channels simultaneously ensures a chip-to-chip time of less than two seconds.

The SG 160 splits the X-axis into two liner slides, each of which carries tool spindles. Both work spindles are in full position control at any time.

The new grinding SG 160 SKYGRIND of Samputensili ensures cycle times at a low comparative cost to traditional manufacturing solutions in the automotive industry.

The SG 160 SKYGRIND is an amazingly productive machine, even faster than traditional dual table grinding machines, featuring a small footprint and lower cost for auxiliary equipment. The most important piece however is the eliminated need for cutting tools creating an extremely green machine.

Movie

G 250 Gear Grinding Machine

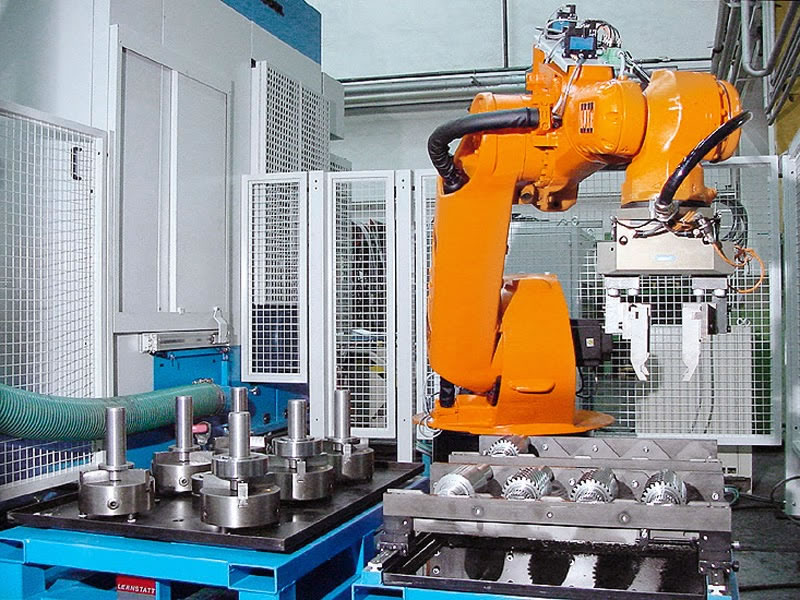

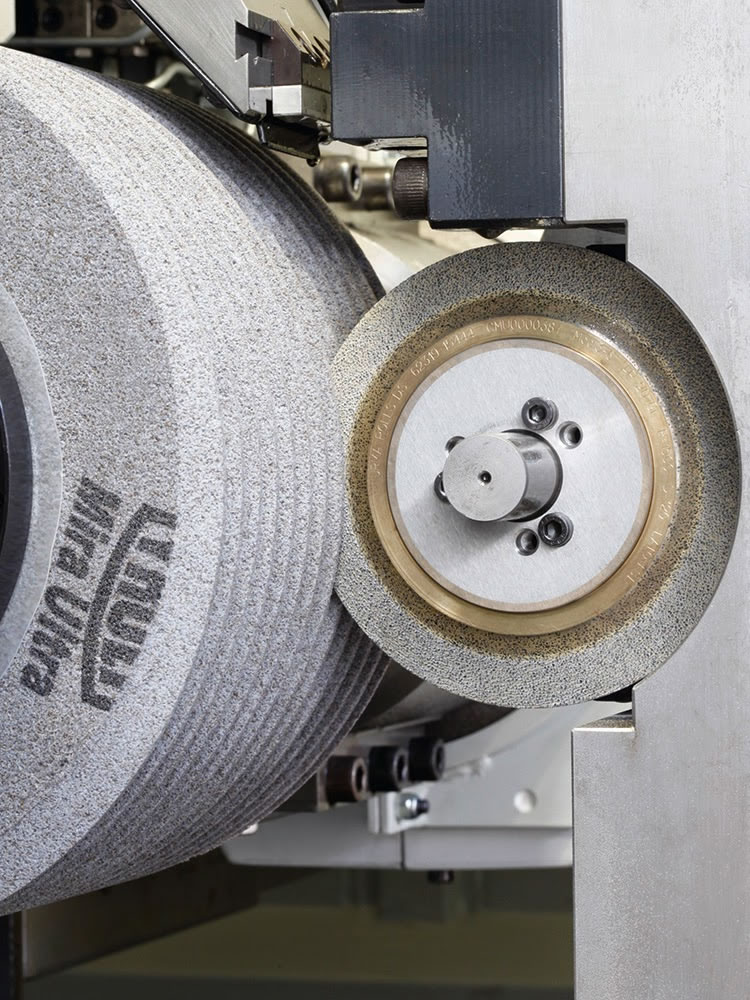

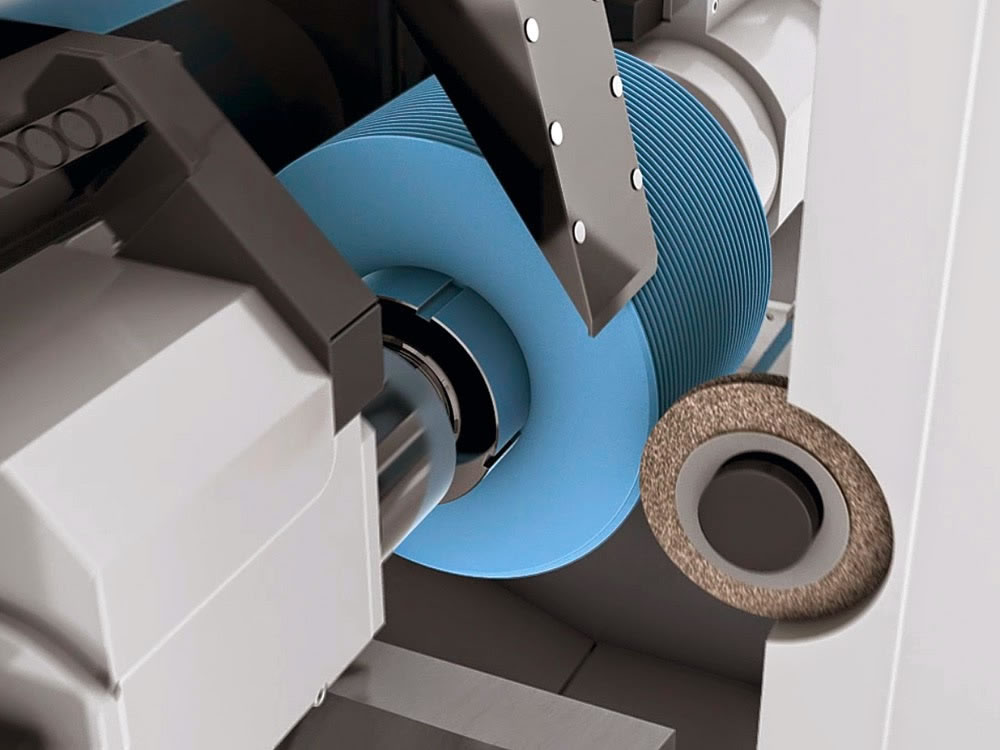

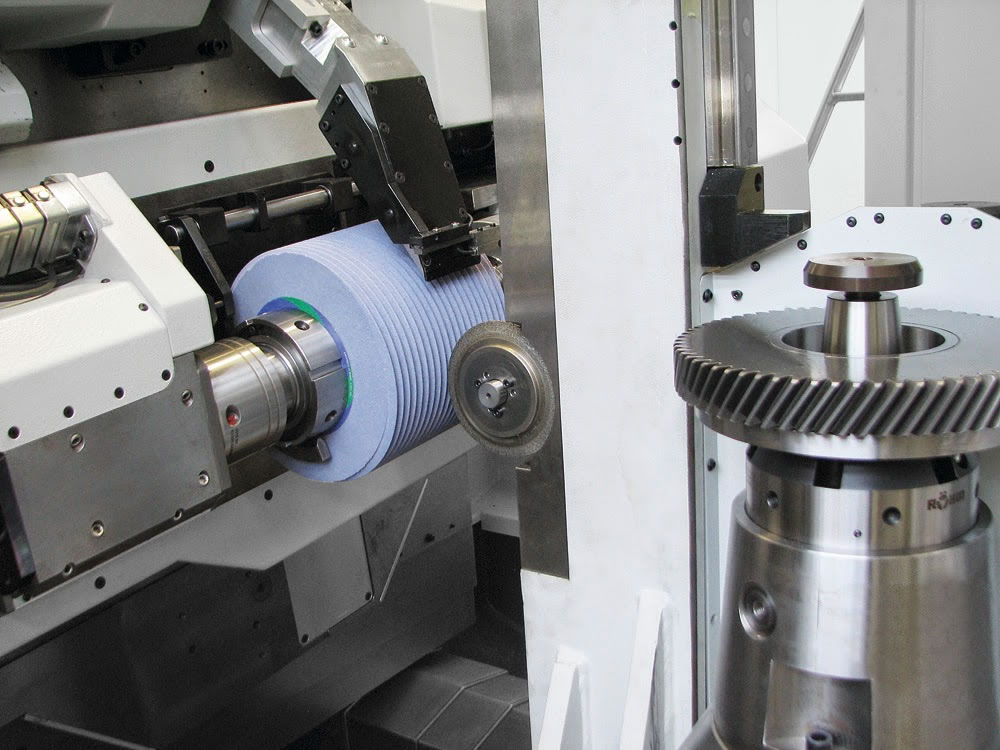

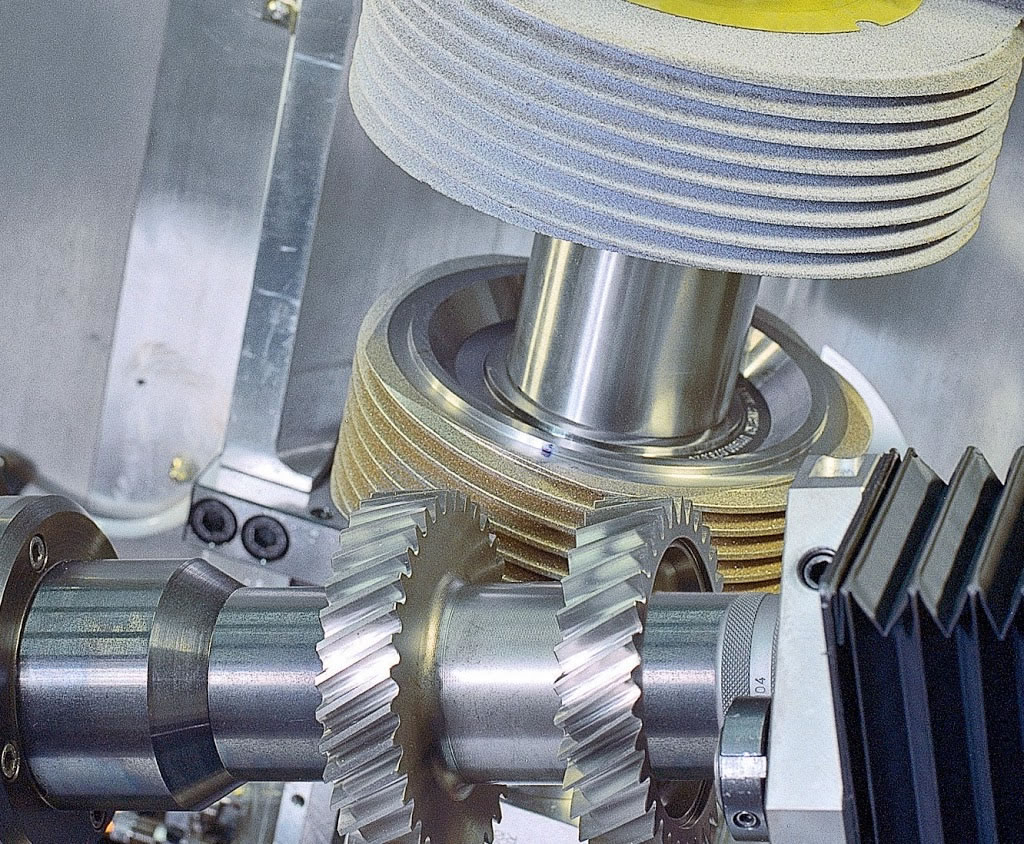

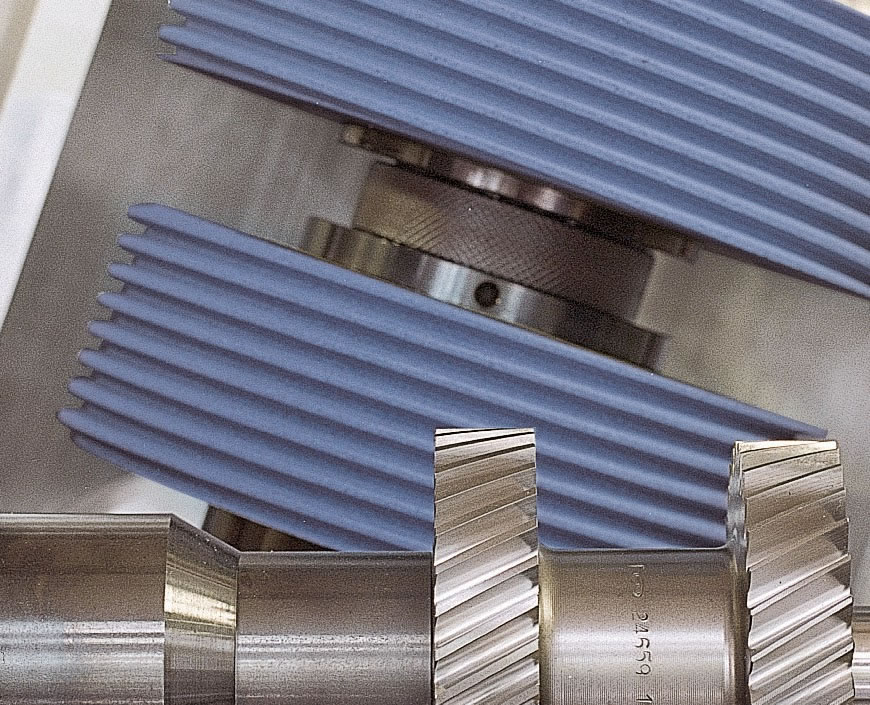

The G 250 generating grinding machine is based on the established concepts of the best-selling Samputensili S 250/400 G machine, which have been further enhanced and improved. The result is an innovative, compact and extremely flexible gear grinding machine. The G 250 has been especially developed for very low cycle times and for top-quality and efficient mass production of gears with outside diameters up to 250 mm and shafts with lengths up to 550 mm. The G 250 features dual work spindles that eliminate non-productive times almost completely. Particular attention has been paid to the state-of-the-art solutions that allow a fast tool change, e.g. from hobbing to grinding, guaranteeing an unmatched process versatility. The machine can equally use form and worm grinding wheels, both in ceramic and in CBN electroplated. Simple design concepts in terms of tooling and dressing technology, fast automation and amazing user-friendliness are the strengths behind this unique machine.

- Features

-

・Very low cycle times

・Dual work spindles to eliminate non-productive time

・Fast tool change from hobbing to grinding,

・Unmatched process versatility.

・Use form and worm grinding wheels, both in ceramic and in CBN electroplated

・Amazing user-friendliness

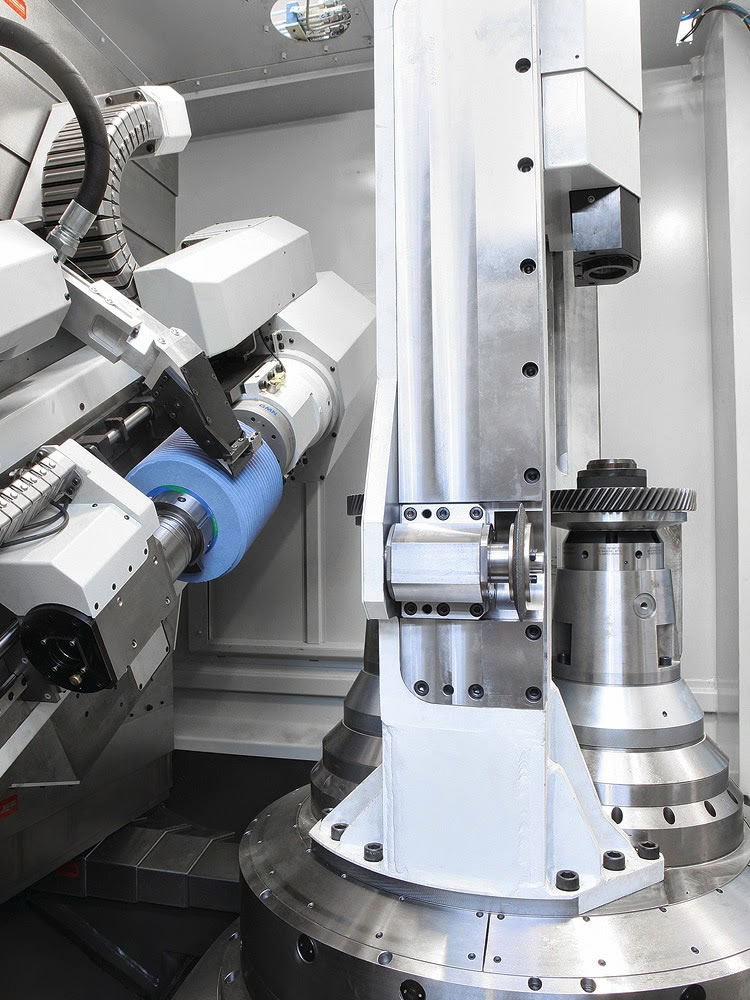

G 450 Grinding Machine

The G 450 is an innovative, compact and extremely flexible gear grinding machine. The G 450 has been especially developed for very low cycle times and for top-quality and efficient mass production of gears with outside diameters up to 450 mm and shafts with lengths up to 550 mm. The machine can equally use form and worm grinding wheels, both in ceramic and in electroplated CBN. Simple design concepts in terms of tooling and dressing technology, fast automation and amazing user-friendliness are the strengths behind this unique machine. The work spindle mounted on a rotating table simplifies the loading/unloading operation as well as the tooling operations. The dressing spindle is mounted on the rotating table as well, but diametrically opposite to the work spindle.

- Features

-

・Very low cycle times

・Dual work spindles to eliminate non-productive time

・Fast tool change from hobbing to grinding

・Unmatched process versatility.

・Use form and worm grinding wheels, both in ceramic and in CBN electroplated

・Amazing user-friendliness

Movie

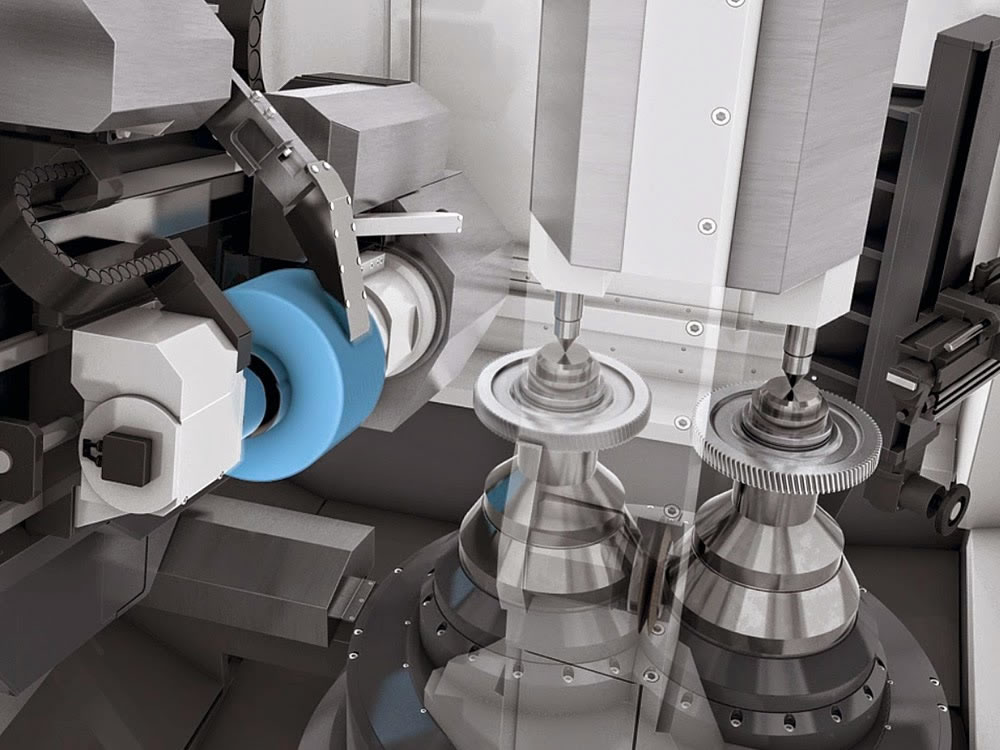

GT 500 H Grinding Machine

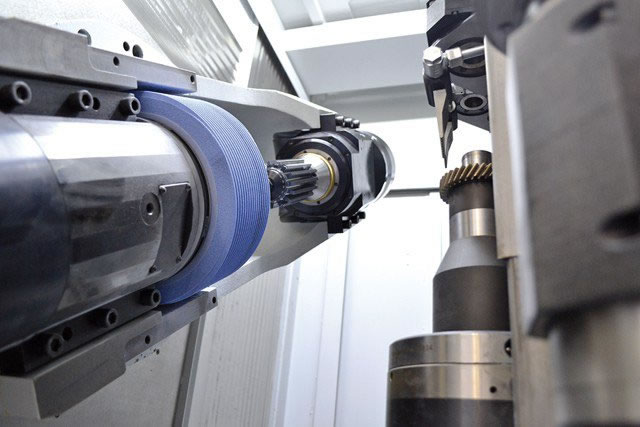

The GT 500 H is designed for profile and generating grinding of spur and helical external gears as well as other profiles that can be generated by hobbing. Built for top-quality, efficient, small, medium and large batch manufacturing of gears and geared shafts, the GT 500 H is a flexible machine well suited for prototyping applications.

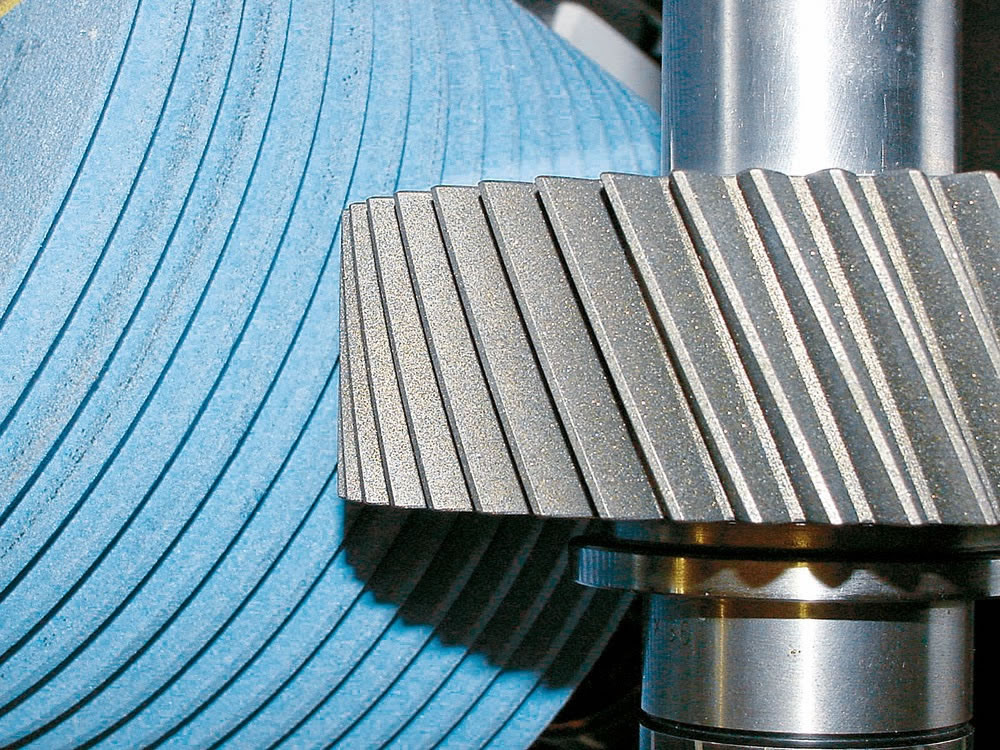

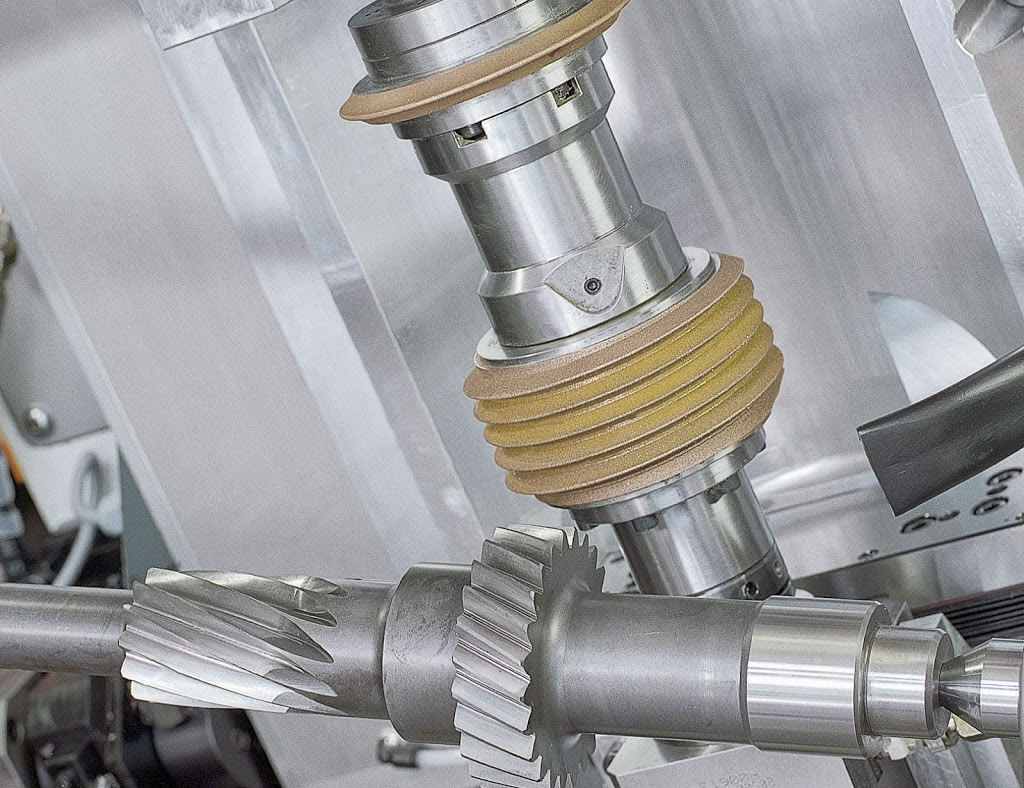

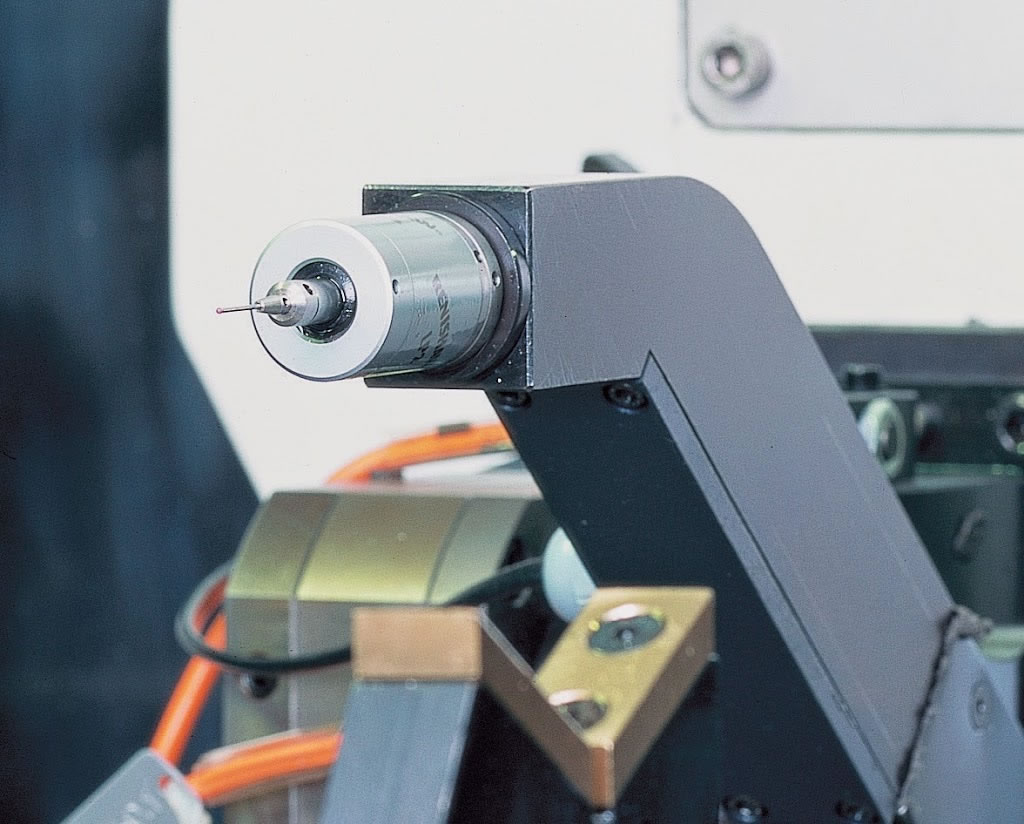

The machine grinds workpieces using the continuous generating grinding method and may mount both dressable and non-dressable worm wheels. Moreover, depending on production requirements, workpieces can also be ground using the profile grinding method (single-indexing method). Again it is possible to mount both dressable and non-dressable grinding wheels and this method may be implemented to grind workpieces singularly or in any preferred combination. Various dressing solutions with dressing rolls are available to dress profile grinding wheels and worm wheels. The centering and measuring unit is fully integrated.

- Features

-

・Generating and profile grinding processes

・Dressable and non-dressable worm wheels

・Optimized operating costs

・Grind workpieces singularly or in any preferred combination

・Fully integrated centering and measuring

・Dressing solutions for both profile and worm grinding wheels

Specs

| Technical Data* | Units | SG 160 | G 250 | G 450 |

|---|---|---|---|---|

| Workpiece diameter, max | mm | 160 | 250 | 250 |

| Module range | mm | 1.0 - 3.0 | 0.5 - 7.0 | 0.5 - 7.0 |

| Workpiece length, max | mm | 300 | 450 | 450 |

| Face width, max | mm | 180 | 350 | 350 |

| Shaft length, max | mm | - | 500 | 500 |

| Helix angle | degree | +95° / -45° | +45° / -45° | +45° / -45° |

| Grinding wheel dia. | mm | 250 max 210 min | 250 / 170 or 120 / 90 | 250 / 170 or 120 / 90 |

| Grinding wheel width | mm | 100 | 180 | 180 |

| Grinding speed, max | m/s | 80 | 80 | 80 |

| Dressing tool dia. | mm | 123 | 120 | 120 |

| Machine overall dimensions L x W x H |

mm | 3,275 x 2,200 x 2,285 | 3,800 x 2,200 x 2,700 | 3,800 x 2,200 x 2,700 |

| Control Siemens | Sinumerik 840 D sl | Siemens 840 D Solution Line |

Siemens 840 D Solution Line |

| Technical Data* | Units | GT 500 H |

|---|---|---|

| Workpiece diameter, max | mm | 160 |

| Module range | mm | 1.0 - 3.0 |

| Profile depth, max. | mm | 1.0 - 20.0 / 1.0 - 25.0 (CBN) |

| Tool head swivel range | degree | +/- 90 |

| Centre dist. work spindle / tool spindle | mm | 32.5 - 362.5 |

| Workpiece length, max. | mm | 950 |

| Axial travel, max. | mm | 900 |

| Radial travel, max. | mm | 330 |

| Tangential travel, max. | mm | 220 |

| Tool spindle power | kW | 48 |

| Ceramic wheel diameter | mm | 80 - 280 (worm) |

| Ceramic wheel thickness, max. | mm | 180 |

| CBN wheel diameter | mm | 220 |

| CBN wheel thickness, max. | mm | 120 |

| Dressing disc diameter, max. | mm | 120 |

| Tool spindle speed, max. | rpm | 0 - 20,000 |

| Work spindle speed | rpm | 0 - 1,000 |

| Workpiece weight, max. | kg | 300 |

| Total connected load / with coolant filtration unit | kVA | 100 |

| Machine weight, including standard equipment | kg | 27,000 |

*Technical data subject to change

Grinding

-

Generating Gear Grinding Machines

Generating Grinding machines feature simple design concepts and user friendly operation. The answer to your generating grinding needs is addressed by two main product families at Samputensili: The GT 500 H and G 250 / G 450.

-

Rotor and Worm Grinding

Perfected of the last 20 years, Samputensili rotor grinding machines reduce machining times and increase productivity.

-

Profile Gear Grinding

Samputensili profile and continuous generating grinding machines use the most advanced tooling technology to provide superior performance.

-

Kesel Rack grinding machine RG 2400

The new Kesel RG 2400 grinding machine completes the Kesel product range for industrial rack production. With its highly innovative design built for quality and high volume productivity this machine is the perfect tool for any rack producer.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.