- English

- Japanese

- TEL

- 81-78-335-7573

Rotor and Worm Grinding

- Models

- Overview

- Mizoguchi Kikai is renowned in the industry for its leadership in designing and manufacturing grinding machines. Their expertise in advanced technology and extensive experience sets them apart, allowing them to deliver high-quality products through precise machining techniques and innovative engineering. Their Rotary Worm Grinding Machine is especially noteworthy, finding applications across various sectors like aerospace and energy industries that demand high-precision grinding. Additionally, Mizoguchi Kikai offers services for modifying and retrofitting existing machines, making them a versatile and reliable partner for businesses seeking tailored solutions.

Models

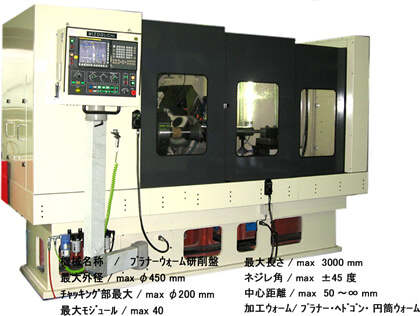

Worm Grinding Machine MKG-900

The MKG-900 Worm Grinding Machine from Mizoguchi Kikai boasts the following features:

- Features

-

- Maximum workpiece center distance of 900 mm, maximum grinding length of 300 mm, maximum workpiece diameter of φ200 mm

- Maximum number of teeth: 10, processing lead range from 0 to infinity mm, helix angle range of ±60 degrees

CNC Device: FANUC

NC Control Axis: Minimum control unit of 0.0001 mm / 0.0001 degrees, radial feed distance of 350 mm, axial feed distance of Z-axis up to 1105 mm, workpiece rotation range of C-axis infinite degrees, grinding wheel rotation range of A-axis ±45 degrees

Movement Speed: Radial feed of X-axis up to 5000 mm/min, axial feed of Z-axis up to 8000 mm/min, workpiece rotation of C-axis up to 30 rpm, grinding wheel rotation of A-axis up to 6 rpm

Motion System: X-axis and Z-axis use LM guides, while C-axis and A-axis use bearings

Lubrication System: Intermittent automatic oiling for X-axis and Z-axis, grease lubrication for C-axis and A-axis

Drive System: X-axis uses ball screws, Z-axis utilizes linear motors, C-axis is direct drive, and A-axis features a worm reduction gearbox

Feedback System: X-axis and Z-axis are full closed-loop (Heidenhain scales), C-axis is full closed-loop (Heidenhain encoders), A-axis is semi-closed-loop (motor pulse coder)

Worm Grinding Machine MKG-1500

The MKG-1500 Worm Grinding Machine from Mizoguchi Kikai has the following features:

- Features

-

- Maximum workpiece center distance of 1500 mm, maximum grinding length of 950 mm, maximum workpiece diameter of φ250 mm

- M18 module, maximum number of teeth: 10, processing lead range from 0 to infinity mm, helix angle range of ±45 degrees

CNC Device: FANUC

NC Control Axis: Minimum control unit of 0.0001 mm / 0.0001 degrees, radial feed distance of 350 mm, axial feed distance of Z-axis up to 1105 mm, workpiece rotation range of C-axis infinite degrees, grinding wheel rotation range of A-axis ±45 degrees

Movement Speed: Radial feed of X-axis up to 5000 mm/min, axial feed of Z-axis up to 8000 mm/min, workpiece rotation of C-axis up to 30 rpm, grinding wheel rotation of A-axis up to 6 rpm

Motion System: X-axis and Z-axis use LM guides, while C-axis and A-axis use bearings

Lubrication System: Intermittent automatic oiling for X-axis and Z-axis, grease lubrication for C-axis and A-axis

Drive System: X-axis uses ball screws, Z-axis utilizes linear motors, C-axis is direct drive, and A-axis features a worm reduction gearbox

Feedback System: X-axis and Z-axis are full closed-loop (Heidenhain scales), C-axis is full closed-loop (Heidenhain encoders), A-axis is semi-closed-loop (motor pulse coder)

Rotor Grinding Machine MKG-900

Mizoguchi Kikai's MKG-900 Rotary Grinding Machine has the following features:

- Features

-

- Maximum workpiece center distance of 900 mm, maximum grinding length of 300 mm, maximum workpiece diameter of φ200 mm

- Maximum number of teeth: 10, processing lead range from 0 to infinity mm, helix angle range of ±60 degrees

Maximum Grinding Wheel Sizes:

- Standard Grinding Wheel: Outer diameter max φ500 x Width max 60

- CBN Grinding Wheel: Outer diameter max φ400 x Width max 40

CNC Device: FANUC

NC Control Axis: Minimum control unit of 0.0001 mm / 0.0001 degrees, radial feed distance of 350 mm, axial feed distance of Z-axis up to 1105 mm, workpiece rotation range of C-axis infinite degrees, grinding wheel rotation range of A-axis ±45 degrees

Movement Speed: Radial feed of X-axis up to 5000 mm/min, axial feed of Z-axis up to 8000 mm/min, workpiece rotation of C-axis up to 30 rpm, grinding wheel rotation of A-axis up to 6 rpm

Motion System: X-axis and Z-axis use LM guides, while C-axis and A-axis use bearings

Lubrication System: Intermittent automatic oiling for X-axis and Z-axis, grease lubrication for C-axis and A-axis

Success Story

Video

Specs

| Technical Data* | Units | MKG-900 | MKG-1500 | MKG-900 |

|---|---|---|---|---|

| Maximum Workpiece Diameter | mm | φ280 | φ280 | φ200 |

| Module | mm | M18 | M18 | - |

| Maximum Tooth Length | mm | - | - | 35 |

| Tool Head Swivel Range | degree | ±45 | ±45 | ±60 |

| Work/Tool Spindle Axis Distance | mm | - | - | - |

| Maximum Workpiece Length | mm | 900 | 1,500 | 900 |

| Maximum Axial Movement | mm | 820 | 1,105 | 900 |

| Maximum Radial Movement | mm | 350 | 350 | 350 |

| Main Spindle Power | kW | 3.7/5.5/7.5 | 3.7/5.5/7.5 | 7.5/11/15 |

| Ceramic Grinding Wheel Diameter | mm | φ500 | φ500 | φ500 |

| Maximum Ceramic Grinding Wheel Width | mm | 60 | 60 | 60 |

| CBN Grinding Wheel Diameter | mm | - | - | φ400 |

| Maximum CBN Grinding Wheel Width | mm | - | - | 40 |

| Maximum Dresser Disc Diameter | mm | φ170 | φ170 | φ160 |

| Maximum Tool Spindle Speed | rpm | 2,800 | 2,800 | 3,000 |

| Work Spindle Speed | rpm | 30 | 30 | 30 |

*Technical data subject to change

Seibu Shoko’s After Service/Maintenance

As an option, Seibu Shoko's regular maintenance can be added. The details of the regular maintenance are as follows:

Periodic Inspection and Cleaning: Conduct regular inspections and cleaning of the machine to check its operation, the condition of components, and detect any issues early.

Parts Replacement: Plan regular replacement of worn-out parts and consumables to maintain the machine's performance and durability.

Sensor Calibration: Calibrate and adjust sensors used in the NC control axis and feedback system to maintain the machine's accuracy.

Operation Testing and Adjustment: Perform regular operation tests to verify the accuracy and stability of the machine, and make adjustments as necessary.

Documentation Update: Properly manage documents such as maintenance records and parts replacement history to facilitate smooth machine management.

Grinding

-

Generating Gear Grinding Machines

Generating Grinding machines feature simple design concepts and user friendly operation. The answer to your generating grinding needs is addressed by two main product families at Samputensili: The GT 500 H and G 250 / G 450.

-

Rotor and Worm Grinding

Perfected of the last 20 years, Samputensili rotor grinding machines reduce machining times and increase productivity.

-

Profile Gear Grinding

Samputensili profile and continuous generating grinding machines use the most advanced tooling technology to provide superior performance.

-

THE R Series Rack Grinding Machines (G Line)

With Kesel’s latest grinding machine, the R-Series G Line, large-volume gear rack profile grinding is achieved with greater speed and precision than ever before.It enables you to meet your productivity and quality goals in a short timeframe.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.