- English

- Japanese

- TEL

- 81-78-335-7573

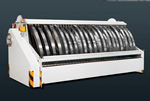

Kesel Bandsaw blade milling machine FS 2500

- Overview

-

The FS 2500 is successor to the FS 2000. After successfully launching the FS 1500 Kesel is now introducing a new revised machine to its range of big bandsaw blade milling machines. It features the high quality Siemens CNC Sinumerik 840D sl control system as well as optimized Siemens servo drive units. Improvements to many areas of the machine increase productivity, quality, efficiency and operability.

The machine has been optimized for an efficient tooth profile milling of carbon and bi-metal bandsaw blades as well as backing material for carbide-tipped bandsaw blades up to a bandwidth of 125 mm and a profile milling range of 32 – 0.5 tpi. Employing the new F 2500 bandsaw blade milling machine in your production process guarantees advantages such as fully automatic feed-through milling, short cycle times, optimal results for tooth geometry and cutting edges as well as the reliablility of the extensive safety equipment.

Options

- Additional milling accessories

- Additional clamping equipment

- Coiling system

- Cutter changing unit

Specs

| Technical Data* | |

|---|---|

| Milling head | |

| Type | F 350 modified transmission with increased power drive |

| Power | 45 kW S6 40 % |

| RPM | max. 450 rpm infinitely variable |

| Milling arbor | SK 50 |

| Min. diameter of milling cutter | 165 mm + 2 x milling depth + 5 mm safety + resharpening (acc. to manufacturer) |

| Max. diameter of milling cutter |

310 mm (depending on cutter cone angle / rake angle saw) |

| Max. tool width |

240 mm; technical assistance with the cutter design upon request |

| Rotational axis | Cutting angle swivel range up to 20 ° |

| Control | |

| Control | Siemens SINUMERIK 840D sl |

| Clamping system | |

| Clamping system | New clamping system with 40 % reduced lifting on clamping jaw and longer life time. |

| Clamping width |

60 mm |

| Band guide and burr plate | |

| Band guide and burr plate | Adjustable in vertical and horizontal direction Electrically operated burr plate drive |

| Coolant and swarf removal | |

| Cooling lubricant | Emulsion |

| Filling capacity | 900 litres |

| Fine filtration | Magnetic filter roller for fine filtration |

| Electrical connection | |

| Voltage | 3 x 400 V |

| Amperage | 80 A |

| Dimensions and weight | |

| Installation dimensions (LxDxH) | 2,230 x 3,570 x 2,510 mm |

| Machine weightapprox | approx. 13,000 kg (incl. control cabinet) |

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.