- English

- Japanese

- TEL

- 81-78-335-7573

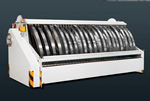

Kesel Band setting machine TSM 160s

- Overview

- The design of the Kesel TSM 160s is based on our many years of experience in building machines for the bandsaw blade production. The Kesel TSM-machines perfectly complement the existing Kesel products ranging from our milling machines FS 1500 and FS 2500 and various coil handling systems to the SBA-2s machine and the BR-100s band straightening machine. As our customers have come to expect from us, these machines combine highest quality and performance with first class service for the customer.

Specs

| Technical Data* | |

|---|---|

| Work piece data | |

| Band width min. | 10 mm |

| Band width max. | 90 mm |

| Band thickness | min.0,6 mm |

| Band thickness max. |

1,65 mm |

| Band material | Bi-Metal not hardened, Bi-Metal hardened |

| Control | |

| Control | Siemens SIMATIC HMI IPC |

| Operation system | Windows 7 |

| Clamping system | |

| Clamping system | Elektric lever system clamping |

| Setting accuracy | |

| Setting tolerance | ± 0,02 mm |

| Symmetry tolerance | ± 0,02 mm |

| Tooth pitch | 0,5 TPI - 32 TPI |

| Max. stroke length | 160 mm |

| Output | |

| Output | 250 - 780 m/h |

| Coiling system | |

| Interface coiling system | included |

| Coiling system | optional |

| Properties | |

| Measuring system | Outgoing measuring system |

| Auto adjustment | Auto adjust setting width, Auto adjust symmetry |

| Measuring log | Yes |

| Band feed system | Programmable roller feed mechanism |

| Band cleaning | Blowing nozzle + brushes |

| Setting tools | resharpable, slot key positioning |

Special Purpose Machinery

-

Kesel Bandsaw blade milling machine FS 1500

The new FS 1500 is a highly productive machine based on decades of expertise in manufacturing special purpose milling machines for milling teeth in carbon and bimetal bandsaw blades of up to 80 mm band width and within the milling range of 32 – 1.4 teeth per inch.

-

Kesel Bandsaw blade milling machine FS 2500

The FS 2500 is successor to the FS 2000. After successfully launching the FS 1500 Kesel is now introducing a new revised machine to its range of big bandsaw blade milling machines.

-

Kesel vertical / horizontal bandsaw blade coiling systems

Our horizontal and vertical coiling systems, developed in-house, interface with our bandsaw blade milling machines to create complete systems for the fully automatic feed-through milling of up to 40 bands.

-

Kesel Band setting machine TSM 160s

The design of the Kesel TSM 160s is based on our many years of experience in building machines for the bandsaw blade production.

-

Kesel Cross serrated flange milling machine CSF

The Kesel CSF machine is especially engineered and built for tooth profile milling of cross serrated flanges and covers a wide range of customary parts.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.