- English

- Japanese

- TEL

- 81-78-335-7573

SEARCH

HBCD

- Overview

-

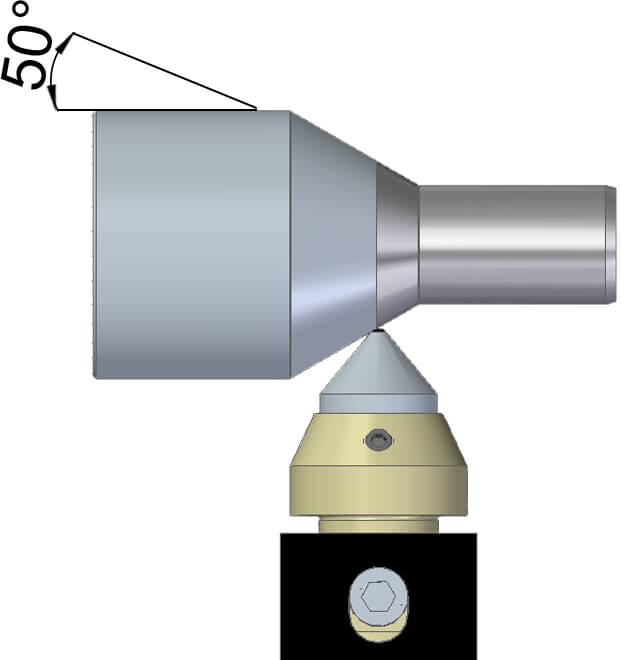

DIAMOND BURNISHING SYSTEM

1.Prior to burnishing, make sure that the turning surface roughness is not higher than Ra 4. Higher roughness can damage the diamond tip. In case it is not possible to achieve the required pre-roughness value, it is recommended to burnish the surface with a roller burnishing tool to Ra<4 before using the diamond burnishing tool.

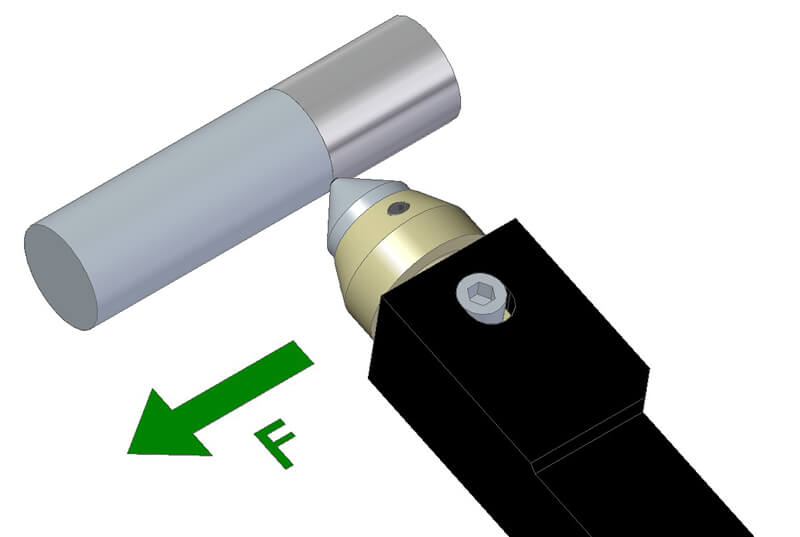

2. Place the diamond tip aligned with the part rotation axis and perpendicular (if possible) to the surface to be burnished.

3. The tool head, where the diamond tip is mounted, is supplied preloaded. The spring system allows a maximum compression of 1.0 mm. However, it is recommended that the pressure to be exerted with the diamond on the surface of the part should not exceed 0.1 mm in ferrous materials and 0.005 mm in non-ferrous materials.

4. Feed with f=0.05-0.20 mm/turn. always work with coolant to achieve a better burnishing finish and avoid diamond damage.

Features

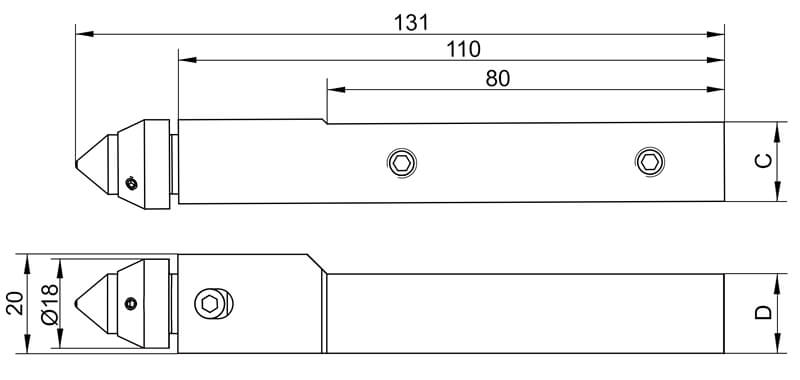

• Tool designed for external diameters of various shapes on sliding head lathes

• Centred shank

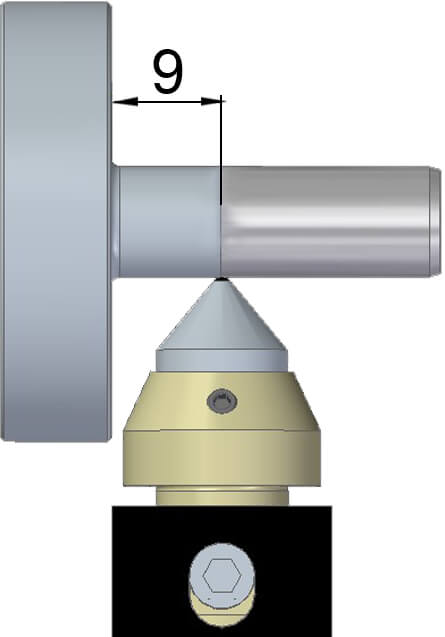

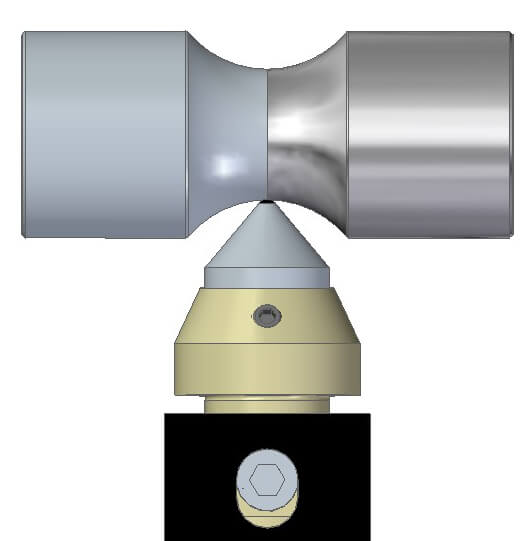

• The head is equipped with an internal spring system to regulate the pressure of the diamond tip, making it homogeneous on all parts (Fig.1)

• Can be used on workpieces made of different types of materials with hardness up to 63 HRC

• Possibility of placing the diamond tip in different positions to extend the life of the tool

Specs

| Code | Reference | Version | Diamond | C | D | E | Kg |

|---|---|---|---|---|---|---|---|

| 09120200 | HBCD 16 | R + L | DT 12 | 16 | 16 | - | 0,3 |

| 09120100 | HBCD 12 | R + L | DT 12 | 12 | 12 | - | 0,3 |

Select the spare part you need

| Code | Reference | |

|---|---|---|

|

10010104 | DT 12-R0.4 |

|

10010108 | DT 12-R0.8 |

|

10010110 | DT 12-R1.0 |

|

10010120 | DT 12-R2.0 |

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.