- English

- Japanese

- TEL

- 81-78-335-7573

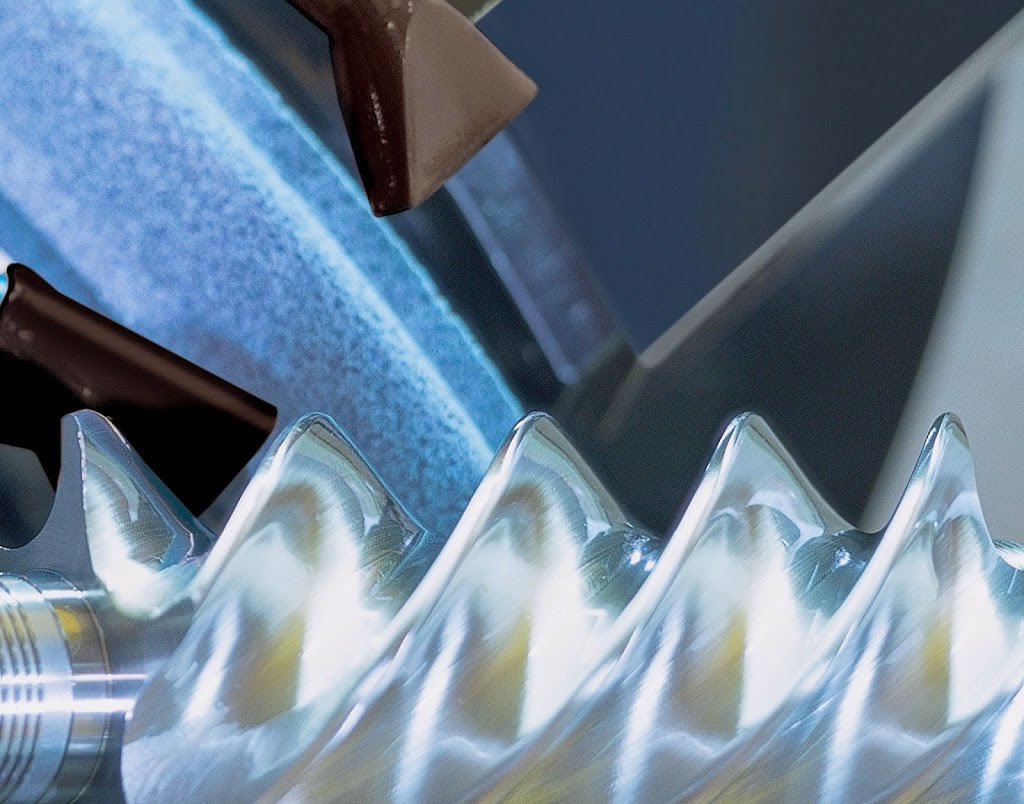

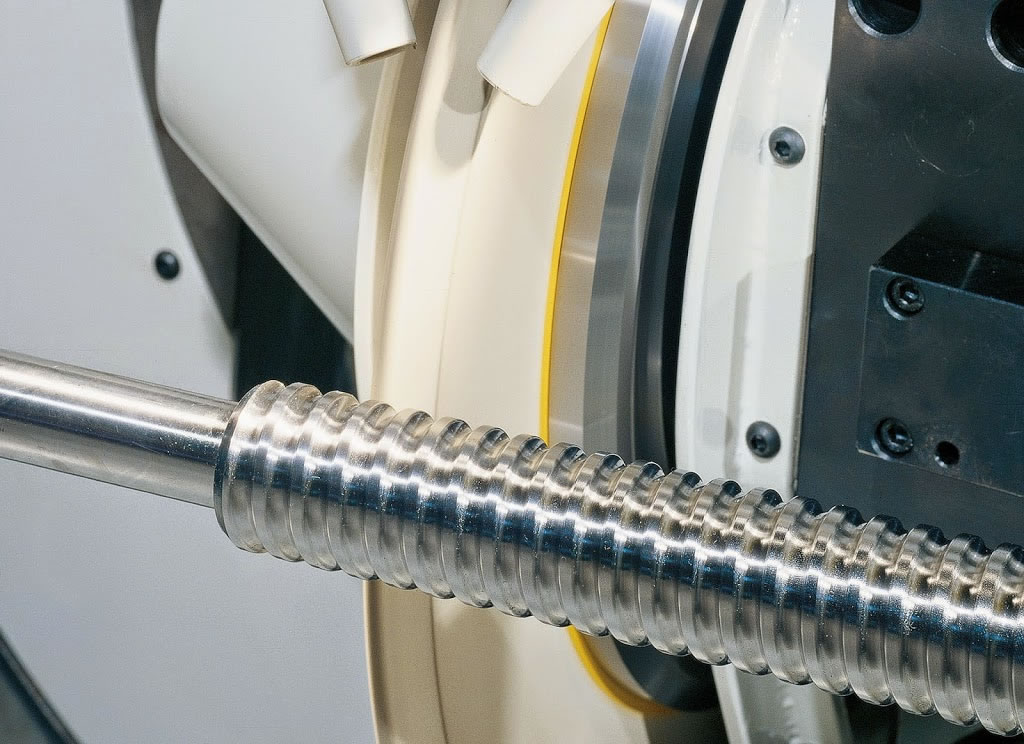

Rotor and Worm Grinding

- Models

- Overview

-

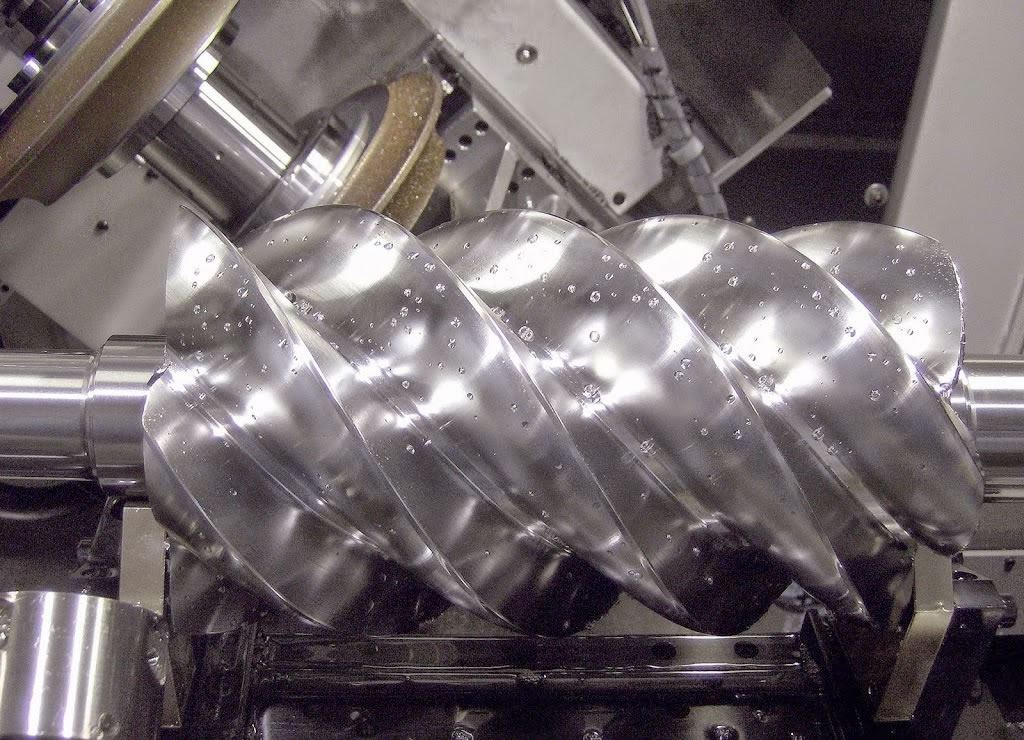

Samputensili developed a specialized and original line of rotor grinding machines during the course of the last 20 years stemming from a need to do their own prototyping and in-house job shopping. The knowledge Samputensili engineers gained translated into a new line of machines as well as the ability to lend customers a helping hand to remove bottlenecks in production or rotor optimization requirements.

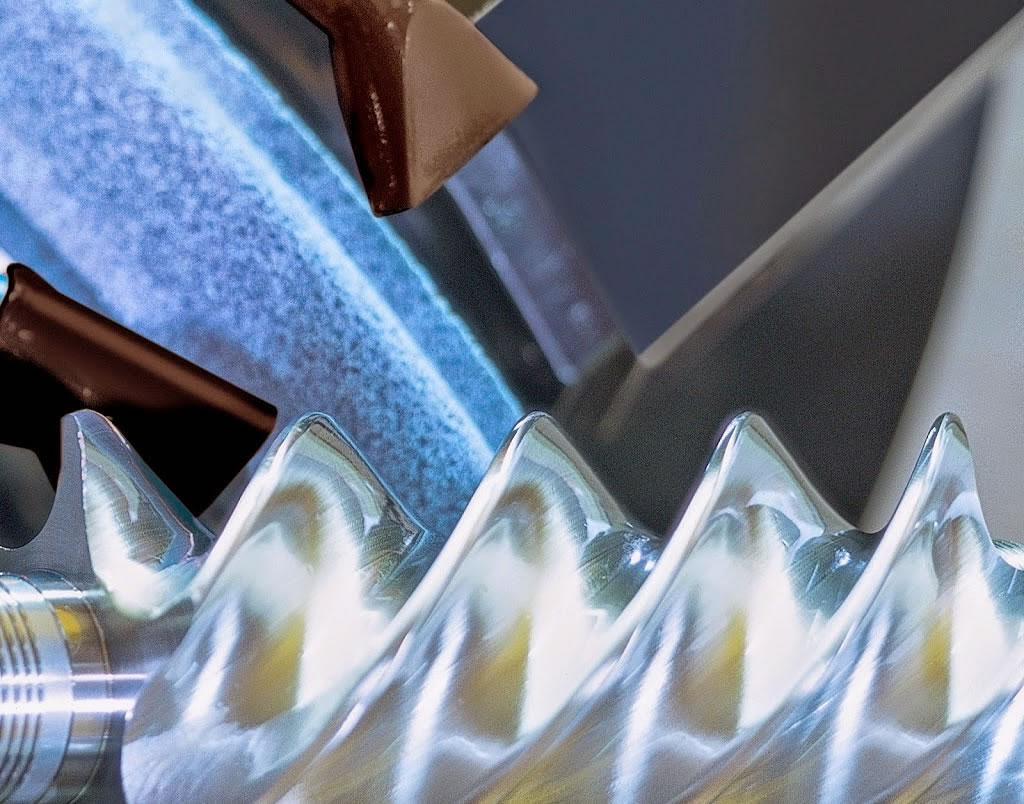

Whether you utilize ceramic grinding tools or electroplated CBN grinding wheels, with the GR series you can produce a great variety of prototype profiles or mass produce just a few different rotor types. Our expert application engineers will help you choose the machine that best suits your size of rotor, your drive output and your tool technology needs.

Models

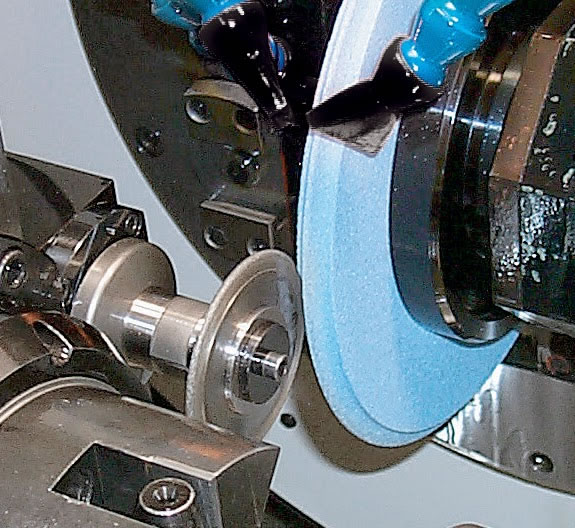

GR 500 H Rotor and Worm Grinding Machine

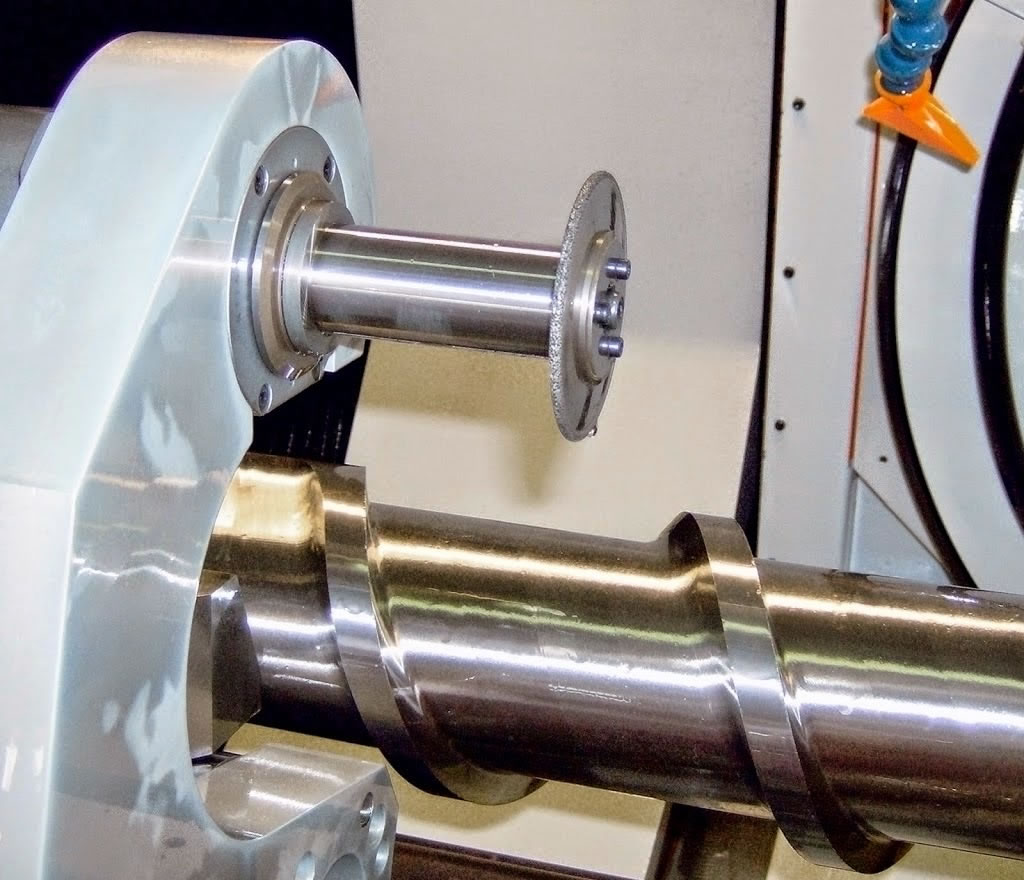

Based on the structure and axis kinematics of the G 500 H, the GR version of the machine is specifically equipped for the manufacturing of rotors. The single grinding spindle allows the operator to grind small to medium lots with unmatched quality, making the GR 500 H an optimal prototyping instrument. Equipped with dressable corundum wheels, integrated dressing and measuring units profile deviations can be auto-corrected immediately.

For larger lot manufacturing we recommend the connection of the machine to an external measuring unit, allowing for maximum efficiency and best results. The GR 500 H comes equipped with a specific rotor software package developed under real rotor manufacturing conditions.

The specific strength of the GR 500 H shows in the flexible manufacturing with dressable corundum wheels. For surface structure requirements and higher speeds you can use CBN grinding wheels as well.

- Features

-

・Based on the structure and axis kinematics of the G 500 H

・Single grinding spindle, dressable corundum wheels

・Integrated dressing and measuring units

・Profile deviations can be auto-corrected immediately

・Specific real-world rotor software package

・CBN grinding wheel capability

Movie

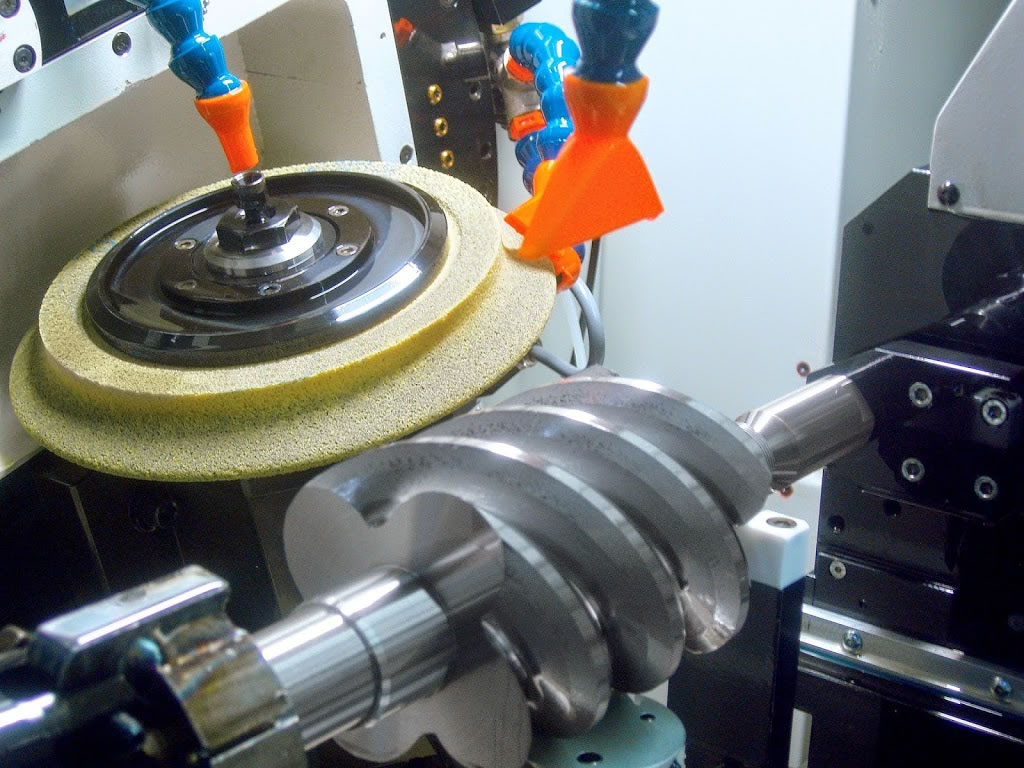

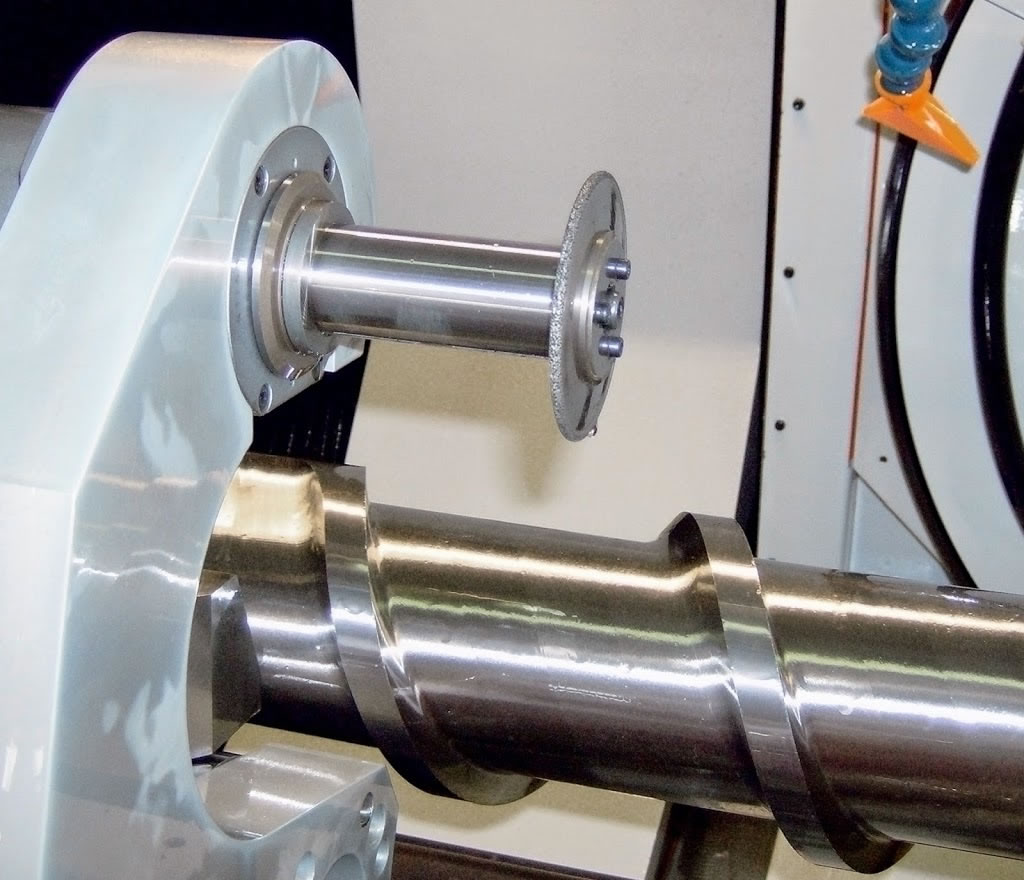

GRX 500 H Rotor and Worm Grinding Machine

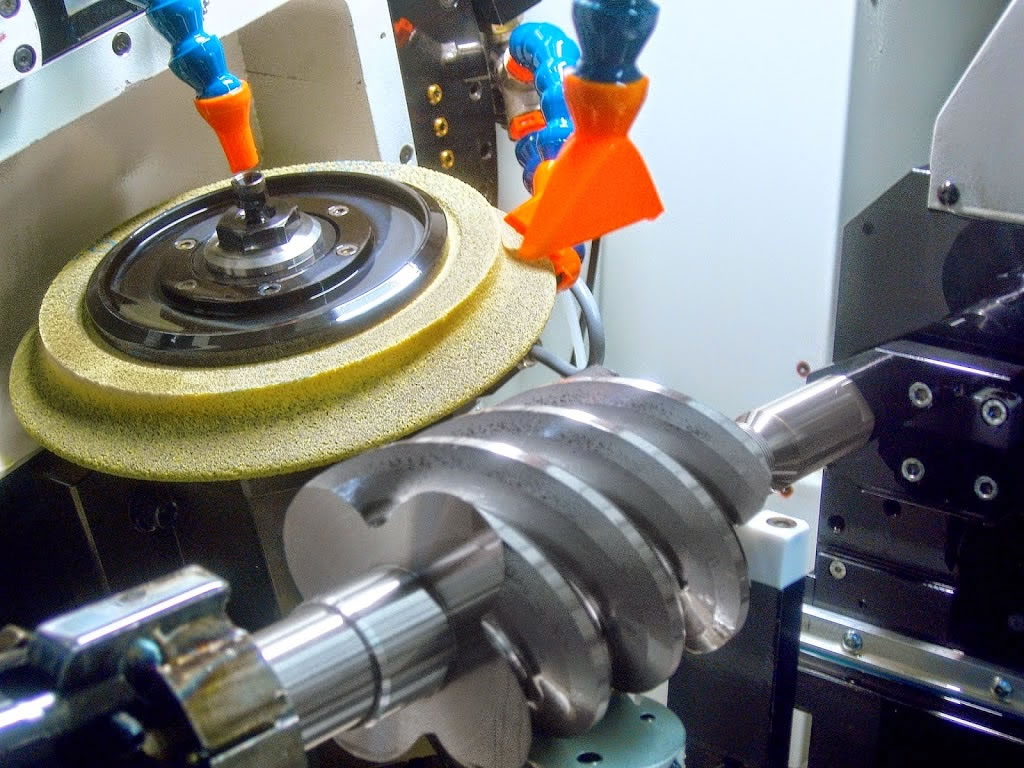

The GRX is a larger and stronger version of the GR. Its powerful twin spindle and extremely stabile bed design make it a must for the manufacture of very large screws and rotors. Especially adapted to grind with CBN, the GRX also makes working with dressable ceramic wheels or even combinations of the two easy.

An integrated measuring unit also makes the correction of rotor prototypes and pre-production pieces more straightforward. For more efficient handling, you can link the GRX to an external robot device and connect it directly with an external measuring unit. Like the GR, the GRX comes with a rotor-specific software package, developed under real manufacturing conditions.

- Features

-

・Based on the structure and axis kinematics of the G 500 H

・Powerful twin spindle and extremely stabile bed design

・Integrated dressing and measuring units

・Profile deviations can be auto-corrected immediately

・Specific real-world rotor software package

・CBN grinding wheel capability

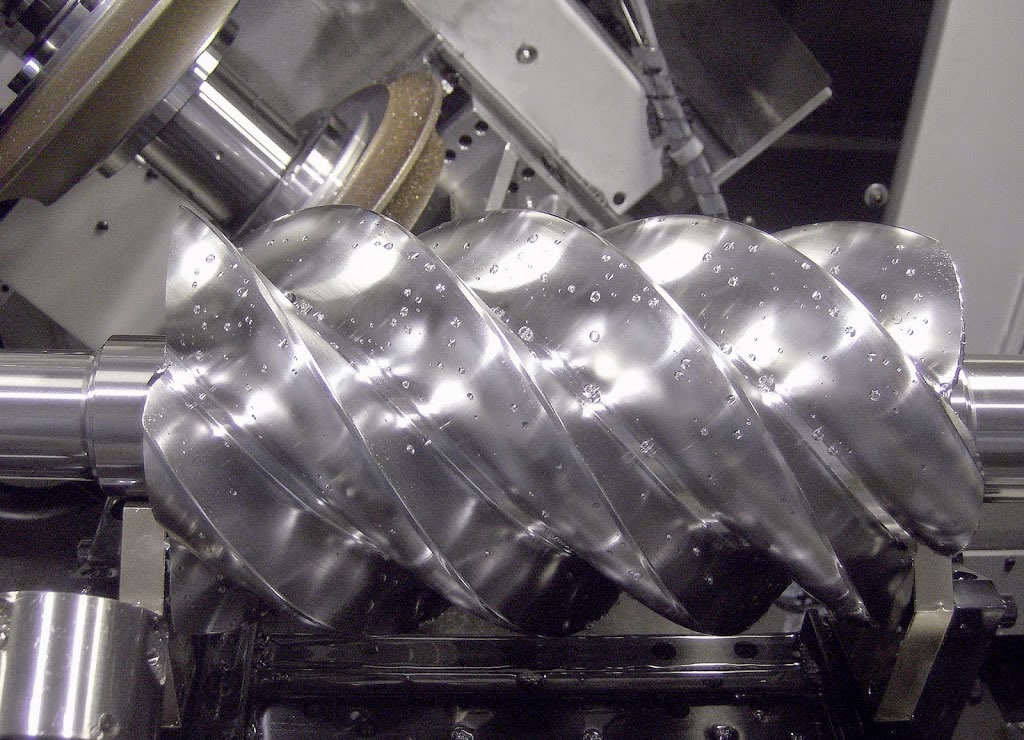

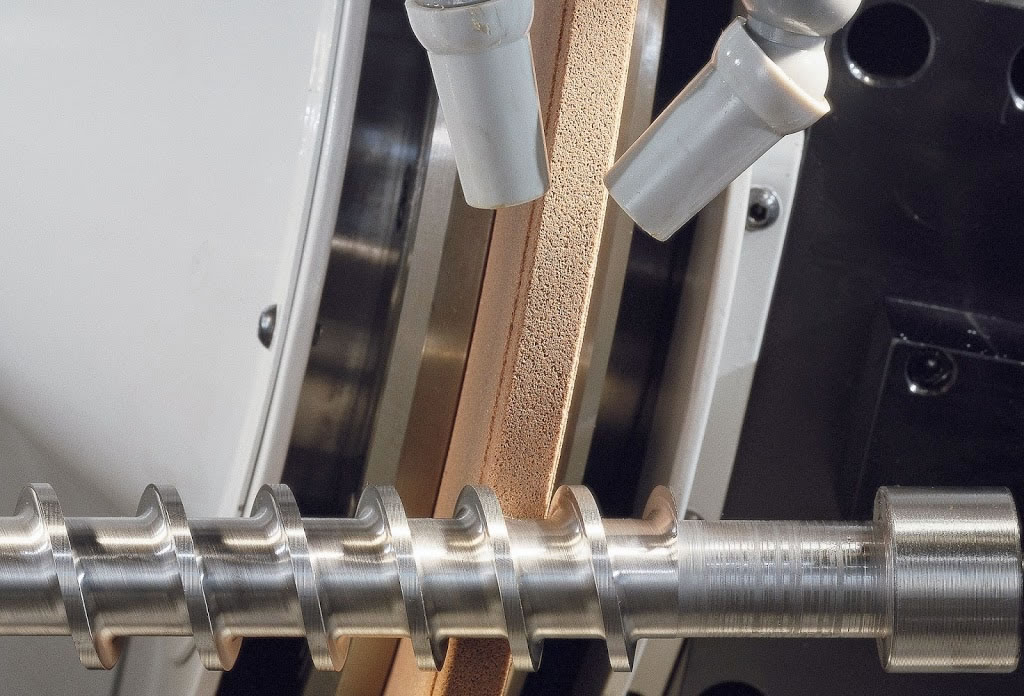

GW 3600 H Rotor and Worm Grinding Machine

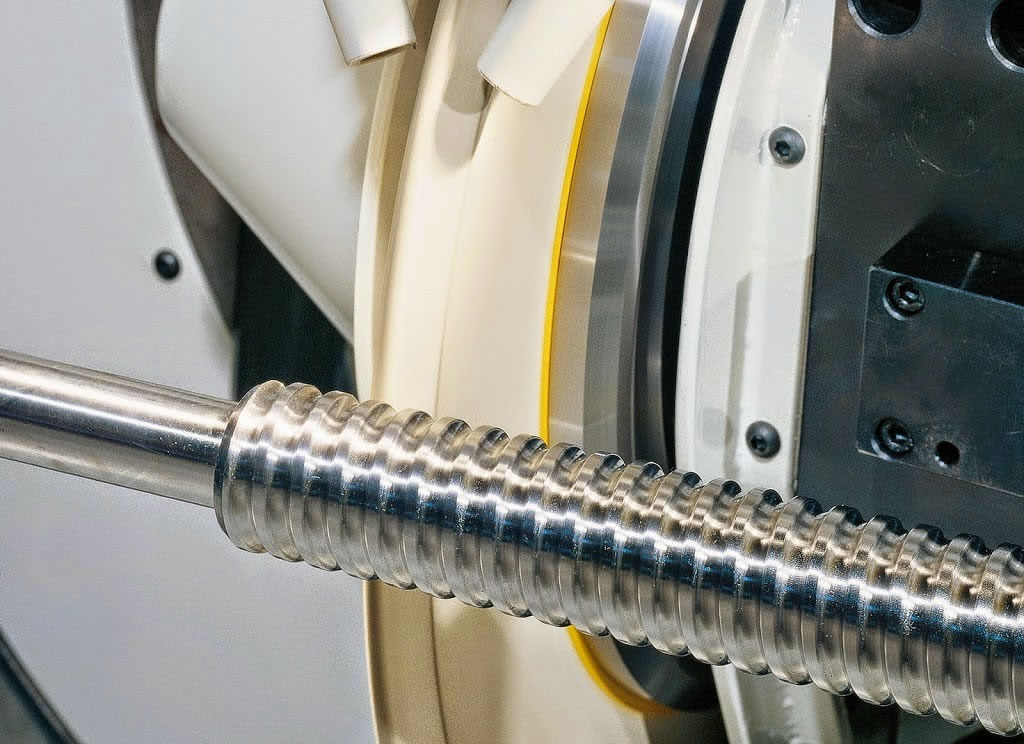

The GW 3600 H is a profile grinding machines for cylindrical or tapered, simple or barrier-type worms and worm segments, with constant or variable leads and in a wide range of profiles. Our machines are also ideal for manufacturing rotors and other screw-type workpieces.

Thanks to the technology and equipment applied to this innovative line of machines (cooling and filtration systems and motors), it is possible to apply the creep feed method, grinding your workpieces from a solid block or machining heat-treated workpieces, whilst obtaining incredibly high performances. This highly specialised range of machines is available in different versions depending on the length and profile depth of your workpieces. Also, with a wide range of dressing units and tool spindles on offer, no job is too complicated for the GW 3600 H.

Our profile grinding program is completed by ceramic and CBN-plated profile grinding wheels for roughing and finishing, and naturally we can address any tool servicing requirement, including CBN stripping and replating. You can purchase your dressing tools either from Samputensili or from your usual supplier. Whatever your requirements and whatever production technology you opt for, with Samputensili you will always have the key to efficient manufacturing without ever compromising on the quality of your end product.

- Features

-

・3600 mm grinding length

・Optional dressing units for ceramic grinding wheels

・Flexible mass production requirements

Specs

| Technical Data* | Units | GR 500 H | GRX 500 H | GW 3600 H |

|---|---|---|---|---|

| Workpiece diameter, max. | mm | 400 | 400 | 250 |

| Module range | mm | n/a | n/a | n/a |

| Profile depth, max. | mm | 52 / 80 | 80 | 40 |

| Tool head swivel range | degree | +/- 90 | +/- 90 | +/- 90 |

| Centre dist. work spindle / tool spindle | mm | 165 - 495 | 32.5 - 460 | 170 - 355 |

| Workpiece length, max. | mm | 1,250 | 1,600 | 3,600 |

| Axial travel, max. | mm | 900 | 1,130 | 3,000 |

| Radial travel, max. | mm | 330 | 427.5 | 185 |

| Tangential travel, max. | mm | n/a | n/a | n/a |

| Tool spindle power | kW | 20 / 35 | 50 | 20 / 35 |

| Ceramic wheel diameter | mm | 300 - 500 | 190 - 340 | 330 - 450 |

| Ceramic wheel thickness, max. | mm | 80 / 120 with shoulders | 145 | 45 / 75 with shoulders |

| CBN wheel diameter | mm | n/a | 280 | n/a |

| CBN wheel thickness, max. | mm | n/a | 100 | n/a |

| Dressing disc diameter, max. | mm | 150 | 70 | 70 |

| Tool spindle speed, max. | rpm | 4,000 | 8,000 | 4,000 |

| Work spindle speed | rpm | 0 - 600 | 0 - 600 | 0 - 400 |

| Workpiece weight, max. | kg | 350 | 450 | 250 |

| Total connected load / with coolant filtration unit | kVA | 150 | 150 | 40 |

| Machine weight, including standard equipment | kg | 15,500 | 30,000 | 18,500 |

*Technical data subject to change

Grinding

-

Generating Gear Grinding Machines

Generating Grinding machines feature simple design concepts and user friendly operation. The answer to your generating grinding needs is addressed by two main product families at Samputensili: The GT 500 H and G 250 / G 450.

-

Rotor and Worm Grinding

Perfected of the last 20 years, Samputensili rotor grinding machines reduce machining times and increase productivity.

-

Profile Gear Grinding

Samputensili profile and continuous generating grinding machines use the most advanced tooling technology to provide superior performance.

-

Kesel Rack grinding machine RG 2400

The new Kesel RG 2400 grinding machine completes the Kesel product range for industrial rack production. With its highly innovative design built for quality and high volume productivity this machine is the perfect tool for any rack producer.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.