- English

- Japanese

- TEL

- 81-78-335-7573

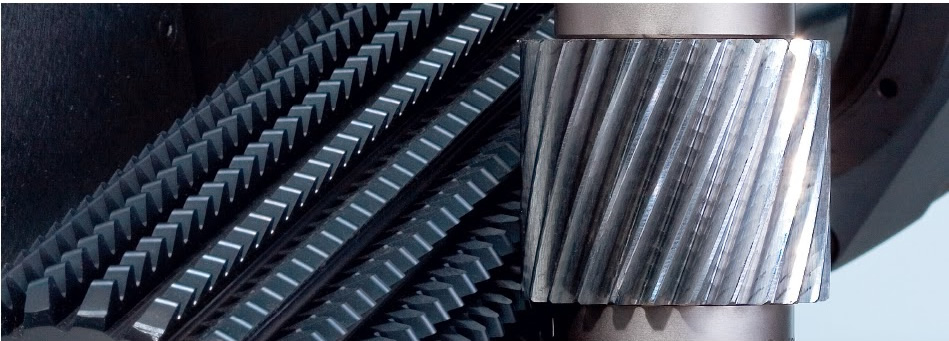

Vertical Hobbing

- Models

- Overview

-

Star SU offers vertical hobbing machines from FFG's brand Modul. These straight & helical gear hobbing machines are designed for a variety of applications and feature an 80 mm to 2300 mm diameter.

Features include

・Automotive Applications

・High-Performance Dry or Wet Hobbing

・Machines for Gears, Shafts, & Screw-type Workpieces

・Large Gear Milling & Hobbing Applications

Models

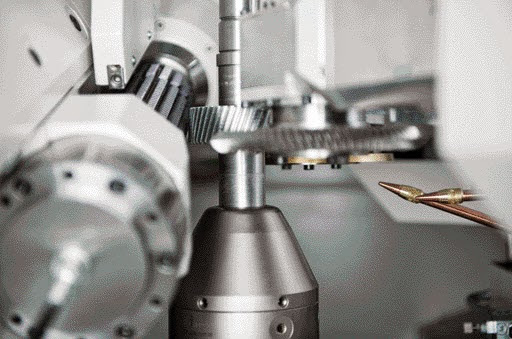

H 80-200 Vertical Gear Hobbing Machine

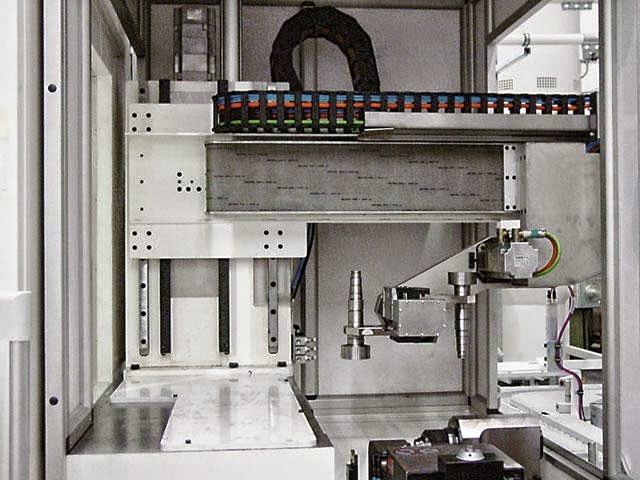

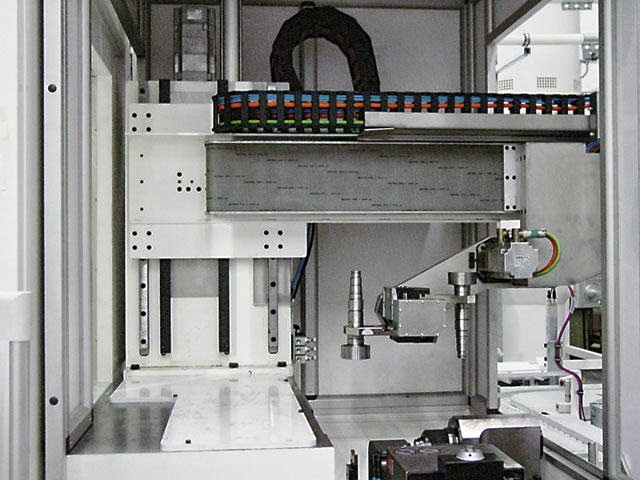

The H 80/100/130/160/200 series is the latest version of our hobbing machine line for small automotive applications, specially engineered for automotive applications. These machines have been designed for dry cutting applications in particular, although using oil or emulsion is not a problem. Chips are conveyed cleanly from the work area by means of a chute, which is steep and smooth in design to prevent any build up. The hob head is housed within the tool column, which is tightly fastened to the sturdy machine bed. The tailstock is located on the tool column above the hob head, leaving the work area remarkably free for workpiece loading and unloading operations.

To cater for your line automation needs, the machine is available with a standard, direct-driven double gripper loader. Placing a machine in close proximity to your workpiece conveyor belt, in fact, requires no further automation other than that provided by the completely integrated solution. All peripheral units are easily accessible and maintenance-friendly (including pneumatics, hydraulics, electrics and chip disposal).

The machines can either be used as high-speed mass production tools or as power houses to obtain high-torque cutting performances, thanks to the different drive variants available. Moreover, the direct drive technology incorporated in this series makes your machine a safe investment over time, since any future tool developments can be fully exploited.

Fast and easy operator guidance throughout the whole process is guaranteed by the latest Siemens Sinumerik 840 D dialogue software, and the ability to make flexible tooth flank and crowned root corrections, ensures optimum roughing results for pre-shave, pre-grind or pre-hone applications.

- Features

-

・Dry cutting

・Chute conveys chips cleanly

・Siemens Sinumerik 840 D control

・Fast and easy operator guidance

・Latest dialogue software

・Flexible tooth flank capability

Movie

H 250-400 Vertical Gear Hobbing Machine

Specially developed for high-performance dry or wet hobbing requirements up to 400 mm in diameter, the H 250/300/400 series is productive for small batches or mass production. Able to machine straight and helical gears; crowned and tapered gears; worm gears; chain sprockets and toothed belt discs; cluster gears and special profiles, this series can utilize any known hob or form milling technology, from dry or wet machining with high capacity HSS or carbide tools to skive hobbing of heat-treated gears. The machine is available with standard ring or portal loaders depending on the application or automation requirement.

- Features

-

・Small batch or mass production

Straight & helical gears

Crowned & tapered gears

Worm gears

Chain sprockets & toothed belt discs

Cluster gears and special profiles

・Optional high-torque worktable

・Longer workpiece & shaft capability

・Use any hob or form milling technology

・Standard ring or portal loaders

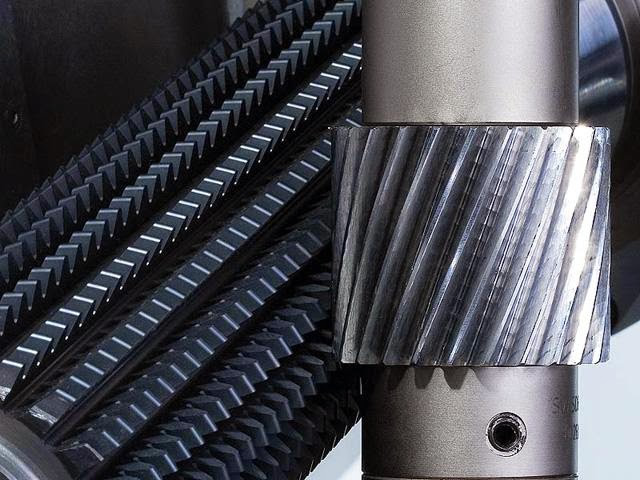

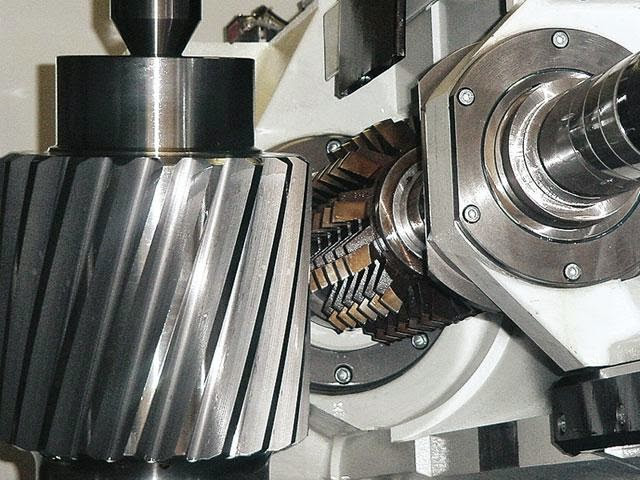

H 600-800 Vertical Gear Hobbing Machine

The H 600-800 is a very stable and rigid machine for the most demanding cutting taks. The machine employs all hobbing techniques (axial, radial/axial, tangential, diagonal) of spur and helical gears using one or multiple cut technology with climb or conventional feed exploiting the different tool solutions available on the market. For workpieces with larger modules and tooth depths the H 600 is also available as a reinforced version, featuring an extra high-torque hob spindle, an enlarged swivel angle range and an extended counter column to cut long and slim shapes like rotors or longer shafts.

The H 600-800 can be equipped with a stable ring loader for heavy workpieces.

- Features

-

・Very stabile, rigid machine

・All hobbing techniques

・Spur and helical gearings

・Single or multiple cut technology

・Climb or conventional feed

・Exceptionally strong tool spindle drive

・Sturdy, stiff tool head

・Special PowerCutting options

・Ring loader for heavy workpieces

H 900-2300 Vertical Gear Hobbing Machine

The H 900-2300 is designed for large gear milling and hobbing applications. The large H series cuts straight and helical gears; crowned and tapered gears; worm gears; cluster gears and special profiles (such as compressor-type rotors); oval gears; herringbone gears (gears with a double helix); and internal gears. This series can utilize any cutting technology available on the market, from single-cut form milling cutters, to HSS or carbide tools for wet or dry hobbing applications, chamer-hobbing. With the optionally available internal milling head intenal gears can be cut as well.

- Features

-

・Straight and helical gears

Crowned and tapered gears

Worm gears

Cluster gears and special profiles

Oval gears

Double helical gears

・Any cutting technology available

・Wet or dry hobbing

・Optional milling head for internal gears

Specs

| Technical Data | Units | H 100 | H 250 | H 300 | H 400 |

|---|---|---|---|---|---|

| Maximum Module | mm | 4 | 4.5 | 4.5 | 4.5 |

| Maximum workpiece dia. | mm | 100 | 250 | 300 | 400 |

| Maximum Axial Cutting Length | mm | 100-450 | 200-600 | 200-600 | 200-600 |

| Maximum Hob Diameter | mm | 90 | 130 | 130 | 130 |

| Maximum Hob Length (bore type) | mm | 190 | 300 | 300 | 300 |

| Maximum Hob Length (shank type) | mm | 285 | 325 | 325 | 325 |

| Maximum Hob Swivel | deg | +/- 45° | +/-45° | +/- 45° | +/-45° |

| Maximum Hob Shift | mm | 325 | 300 | 300 | 300 |

| Hob Speed Range (RPM) | 1/min | 250-3500 | 225-1800 | 225-1800 | 225-1800 |

| Workspindle Maximum Speed (RPM) | 1/min | 1000 | 1-400 | 1-400 | 1-400 |

| Hob Drive Power | kW | 15 | 18.5 | 18.5 | 18.5 |

| Total Connected Load | kVA | 35 | 40 | 40 | 40 |

| Width (Approximate) | mm | 2600 | 2420 | 2420 | 2420 |

| Height (Approximate) | mm | 2850 | 2750 | 2750 | 2750 |

| Length (Approximate) | mm | 2300 | 4000 | 4000 | 4000 |

| Weight (Approximate Net) | kg | 8500 | 11500 | 11500 | 11500 |

| Technical Data | Units | H 600 | H 800 | H 900 | H 2300 |

|---|---|---|---|---|---|

| Maximum Module | mm | 12 | 12 | 24 | 24 |

| Maximum workpiece dia. | mm | 600 | 800 | 900 | 2300 |

| Maximum Axial Cutting Length | mm | 310-760 | 310-760 | 310-1310 | 310-1310 |

| Maximum Hob Diameter | mm | 210 | 210 | 450 | 450 |

| Maximum Hob Length (bore type) | mm | 400 | 400 | 500 | 500 |

| Maximum Hob Length (shank type) | mm | NA | NA | NA | NA |

| Maximum Hob Swivel | deg | +/- 45° | +/- 45° | +/-45° | +/- 45° |

| Maximum Hob Shift | mm | 320 | 320 | 350 | 350 |

| Hob Speed Range (RPM) | 1/min | 100-800 | 100-800 | 32-320 | 32-320 |

| Workspindle Maximum Speed (RPM) | 1/min | 1-100 | 1-100 | 0.1 - 12 | 0.1 - 12 |

| Hob Drive Power | kW | 22 | 22 | 46 | 46 |

| Total Connected Load | kVA | 110 | 110 | 100 | 100 |

| Width (Approximate) | mm | 2700 | 2700 | 4800 | 6000 |

| Height (Approximate) | mm | 3200 | 3200 | 4000 | 4000 |

| Length (Approximate) | mm | 4650 | 4650 | 7300 | 7300 |

| Weight (Approximate Net) | kg | 19000 | 19000 | 26000 | 32000 |

Hobbing

-

Vertical Hobbing

Star SU offers vertical hobbing machines from FFG’s brand Modul. These straight & helical gear hobbing machines are designed for a variety of applications and feature an 80 mm to 2300 mm diameter.

-

Rotor Manufacturing

Star SU offers vertical hobbing machines from FFG’s brand Modul. Worms and worm segments gear hobbing machines feature constant or variable leads and a wide range of profiles.

-

Hobbing Chamfer/Deburr

Hobbing/Chamfer Deburr machines for a variety of applications can include integrated chamfer, deburr, and rolling tools.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.