- English

- Japanese

- TEL

- 81-78-335-7573

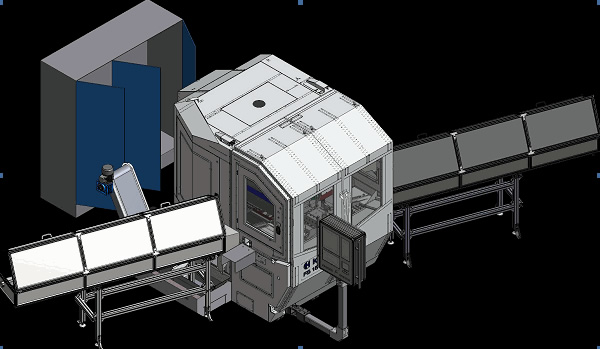

Kesel Automatic Rack Milling Machine

- Overview

-

The Kesel Automatic Rack Milling Machine is designed to mill individual racks automatically with unmanned operation. In addition to the in-feed and out-feed units the machine has built-in reserve storage enabling unmanned operation to be carried out for an entire shift.

Tooth profiles with the following sizes and material cross-sections are possible with lengths of between 500 mm and 2000 mm:

Module 1 (15 mm x 15 mm)

Module 1,5 (20 mm x 20 mm)

Module 2 (25 mm x 25 mm)

Module 3 (30 mm x 30 mm)

Module 4 (40 mm x 40 mm)

Module 5 (50 mm x 50 mm)

Key Advantages:

– Automatic, unmanned operation

– Loading and changing of the cutter can be timed to coincide with shift changes

– Elimination of loading and unloading times

– Machine true running time is approximately equal to the machine operating time

– Manning of a third shift can be achieved without any addition to current manpower

Specs

| Technical Data* | |

|---|---|

| Travel range | |

| X-axis (horizontal, table-axis) | 205 mm |

| Y-axis (vertical, cutting depth) | 230 mm |

| Z-axis (horizontal, infeed) | 370 mm |

| C-axis (adjusting axis) | manual |

| Milling head | |

| Type | F 55.4 |

| Power | 43 kW S6 40 % |

| RPM | max. 315 rpm, stepless adjustable |

| Milling arbor | SK 50 |

| Min. diameter of milling cutter | 128 mm + 2x cutting depth + 5 mm safety + resharpening (acc. to manufacturer) |

| Max. diameter of milling cutter | 250 mm |

| Max. tool width | 200 mm (For cutter design concepts contact Kesel) |

| Control | |

| Control | Siemens SINUMERIK 840D sl |

| Coolant and swarf removal | |

| Cooling lubricant | Emulsion |

| Filling capacity | 390 Liters |

| Fine filtration | Magnetic filter roller for fine filtration |

| Electrical connection | |

| Voltage | 3 x 400 V |

| Amperage | 80 A |

| Dimensions and weight | |

| Installation dimensions | (L x D x H) 7,500 x 2,900 x 2,700 mm |

| Machine weight | ca. 7,200 kg (incl. control cabinet) |

Rack Milling Machine

-

Kesel Rack milling machine RMS

The concept of the RMS machine is based on decades of expertise in manufacturing special purpose milling machines. The machine is equipped with a state of the art Siemens SINUMERIK 840D sl control as well as Siemens servo drive units.

-

Kesel Rack milling machine RMX

The concept of the RMX machine is based on decades of expertise in manufacturing special purpose milling machines. The machine is equipped with a state of the art Siemens SINUMERIK 840D sl control as well as Siemens servo drive units.

-

Kesel Rack milling machine RM

Based on the design of the very successful Kesel RMS and RMX rack milling machines, the RM sets new standards in its class. The cutting area for straight tooth profiles as well as helical tooth profiles has been increased for more productivity.

-

Kesel Automatic Rack Milling Machine

The Kesel Automatic Rack Milling Machine is designed to mill individual racks automatically with unmanned operation. In addition to the in-feed and out-feed units the machine has built-in reserve storage enabling unmanned operation to be carried out for an entire shift.

-

Kesel Steering rack milling machine RMS-Steering

The milling machine RMS-Steering is designed for milling the tooth profile in steering racks. Leading steering rack manufacturers worldwide are milling their tooth profiles on Kesel milling machines.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.