- English

- Japanese

- TEL

- 81-78-335-7573

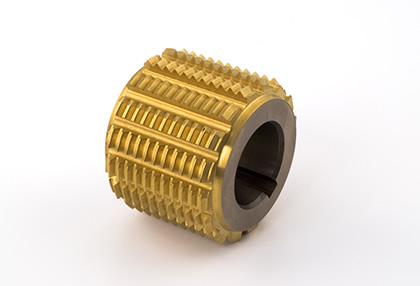

Involute Gear Hobs

- Models

- Overview

- Star SU's complete line of involute gear hobs are designed to provide maximum productivity through increased tool life and less secondary finishing. We carry a complete range of involute gear hobs for your hobbing needs. Learn more about our involute hob types below.

Models

Single Thread Involute Hobs

Single Thread Involute Hobs use straight angled sides for generating gears for maximum accuracy on gear hobbing machines.

- They are normally specified for

-

・Processes where no subsequent tooth finishing operations are required

・Where improved accuracy before tooth shaving operations is required

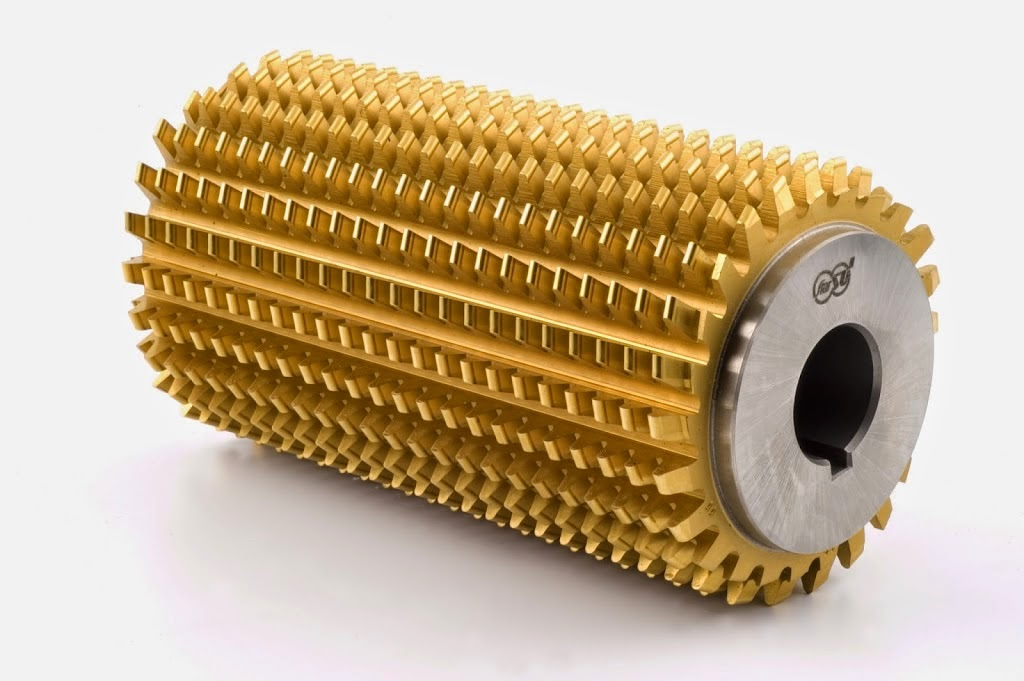

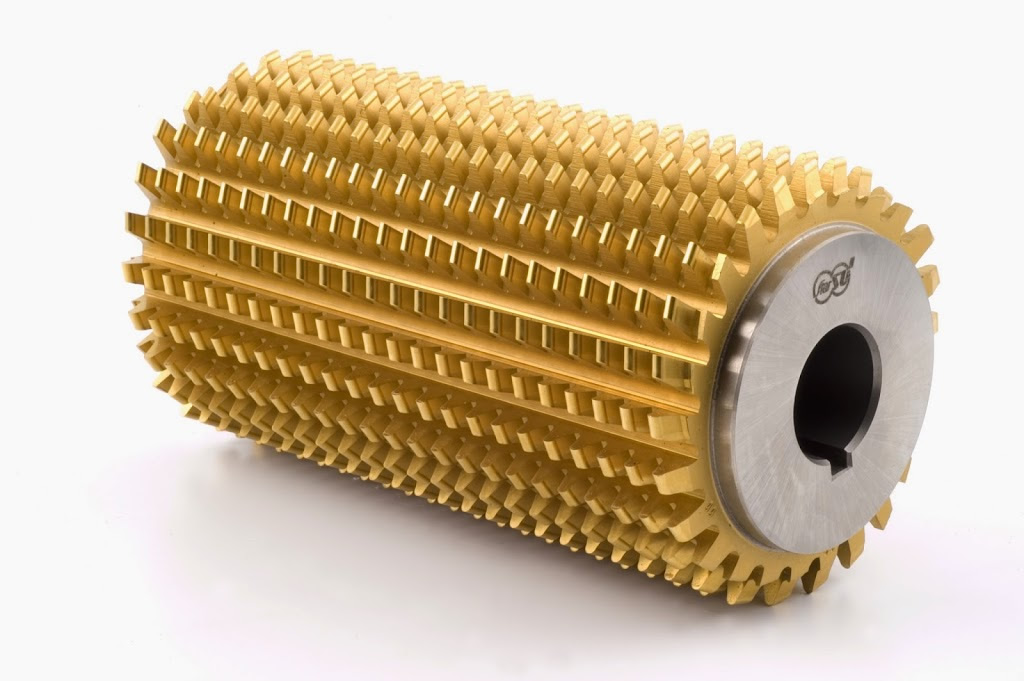

Multiple Thread Involute Hobs

These hobs are designed to increase productivity of the hobbing process. Advancements in hob manufacturing has improved the quality to allow finish hobbing with a multiple thread hob. Depending on the lead angle, they will be either straight or spiral gashed.

Involute Spline Hobs

Involute Spline Hobs have straight sides teeth like a gear hob, and are usually of stub tooth depth. They are made in single or multiple thread designs.

- Diametral Pitches

-

・2.5/5 to 128/256

- Pressure Angles

-

・30°

・37.5°

・45°

Worm Gear Hobs

Worm Gear Hobs are part of specific tools that match the worm shaft with sharpening allowance. This plunge cutting tool is manufactured in shell or shank designs with straight or spiral gash. Lead angles up to 45° are available.

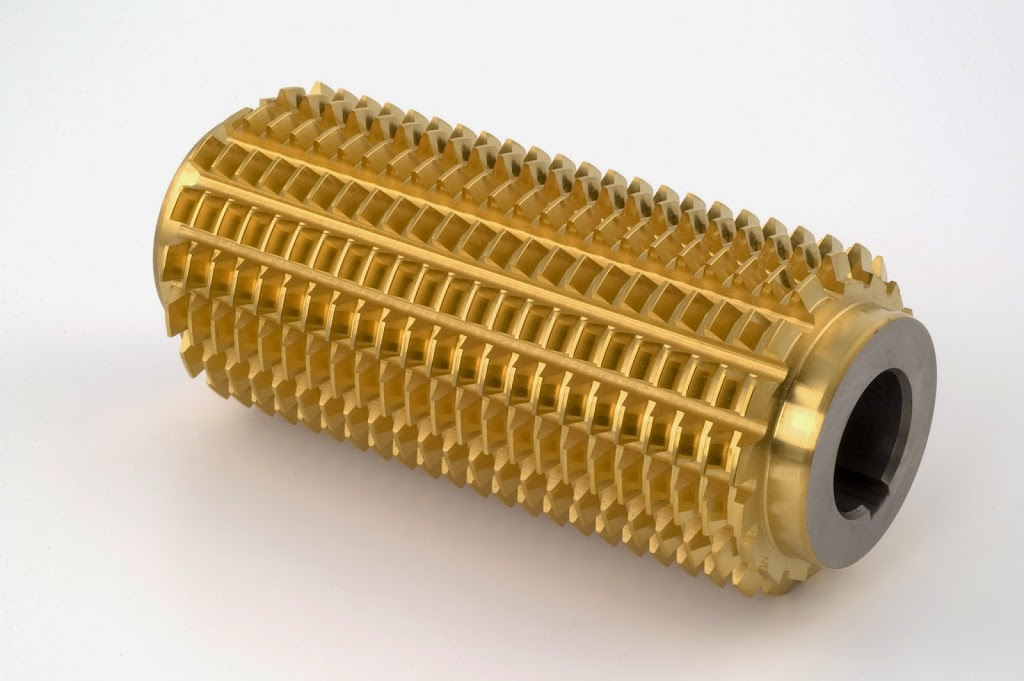

Solid Carbide Hobs

Solid carbide hobs can be used in shell or shank design to cut gears with or without coolant, and are available in shell style with keyway or end drives, and various shank designs to fit most hobbing machines. Both “K” and “P” grade material is offered depending on application.

Hobs

-

Involute Gear Hobs

Star SU provides a large variety of involute gear hobs including single thread, multiple thread, involute spline, worm gear heads, and solid carbide hobs.

-

Non-Involute Gear Hobs

Star SU Non-Involute Gear Hob offerings include sprocket, straight key spline, and special form hobs.

-

Customized Hob Shapes

Customized Hob Shapes can be designed and manufactured to your exact specifications. We provide custom special drive hobs and shank hobs.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.