- English

- Japanese

- TEL

- 81-78-335-7573

Support for your SIEMENS equipments

3 Strengths in Seibu Shoko’s SIEMENS Support

- 1.Accurate Repair

- Our SIEMENS repair service by expert engineers works with the equipment manufacturer to determine whether the equipment can be repaired or not and to identify the fault location. Repair work is carried out in cooperation with the manufacturer to ensure that the repair work does not result in significant modification to the equipment.

- 2.Solutions based on a combination of hardware and software

- Based on our extensive knowledge and experience of hardware, we propose solutions that combine the most appropriate software. In Factory Digitalization, it is necessary to combine knowledge of both the hardware, such as motor and sensors, and the software system that controls them. Experience with software systems is not enough; it is also necessary to have knowledge of the equipment (hardware).

- 3.A Partner of Siemens Solutions

- We have a partnership with Siemens AG for Digital Industries software. This is proof that we are system integrators with expertise in system and process technology. We can support your IT & OT.

SIEMENS Support Services

Seibu Shoko has engineers with specific knowledge and expertise in SIEMENS products and are able to provide a wide range of support based on high-level technical capabilities.

| Repair Support | We will inquire about the condition of the product, the symptoms of the problem, and the details of needed repairs. After diagnosing the problem, we will take prompt and appropriate action to repair any products, or if necessary, make arrangements for appropriate parts. |

|---|---|

| System Proposal/Implementation Support | We propose solutions that include the selection of optimal products and software as well as system design, according to the client’s current issues and requirements. |

| Inspection and Preventive Maintenance | In addition to inspections, we perform maintenance and upkeep on products and equipment to prevent problems and breakdowns. |

| Purchase of Products and Spare Parts | SIEMENS products and parts can be purchased through us. Documentation and manuals for products and systems are also available. |

| Training Support | We provide training on how to use and maintain the systems to help you get the most out of our products. |

| Customization Support | If customization is required, our expert engineers will provide the best customization methods. |

SIEMENS DIGITAL INDUSTRIES SOFTWARE (SISW)

Seibu Shoko handles about 80 different software products from SIEMENS DIGITAL INDUSTRIES SOFTWARE (SISW). Here are some of the representative software products.

-

Analyze MyWorkpiece /Toolpath

Analysis software for machining surface failureAnalyze MyWorkpiece /Toolpath is software designed to optimize the speed and quality of cutting operations involving complex movements. The software visualizes NC program data, data collected with SINUMERIK Operator trace, Analyze MyWorkpiece /Capture, or a generic csv file, and color-codes the toolpath. When a machining failure occurs, it can be deduced whether the cause is the machine tool or the NC program.

Useful for: Quality Managers

-

Adaptive Control & Monitoring (ACM)

Software to Reduce Cycle TimeThis software constantly monitors the spindle load during cutting and uses it to adjust the feed rate. It reduces the feed rate when it cuts the material, when a large load is likely to be applied, and increases the feed rate during cutting, when the load is relatively low. This enables machining not only when the cutter is engaging, but also during machining at the maximum feed rate for each moment, leading to shorter machining times.

Useful for: On-site operators

-

Run MyVirtual Machine

Machine Tool Virtualization (Digital Twin)This software enables machine tools to be digitally twinned. By performing simulations prior to actual machining, it is possible to determine how long the production process will take and to select the optimal CNC program configuration, thereby significantly reducing the cost and time required for prototyping. In addition, by digitally twinning the work area to allow workers to see what they are doing, the software contributes to technical guidance from a remote location.

Useful for: Field Operators & Designers

-

Location Intelligence

Real-time Location Management SoftwareLocation information makes smart factories a reality. This solution enables information on what parts and tools are where, when, and in what condition. This software can be used to eliminate bottlenecks and improve throughput.

Useful for: Field Operators & Designers

-

NX

CAD/CAM/CAE Integrated Software PackageSiemens NX Software is an integrated CAD/CAM/CAE software package with rich functionality and an easy-to-understand interface that greatly improves work efficiency by allowing easy editing of data without history, such as STEP, IGES, and JT. It is a single software package that can support the entire development process, including product design, manufacturing, and simulation.

Useful for: Designers

Frequently Asked Questions

Repair Related

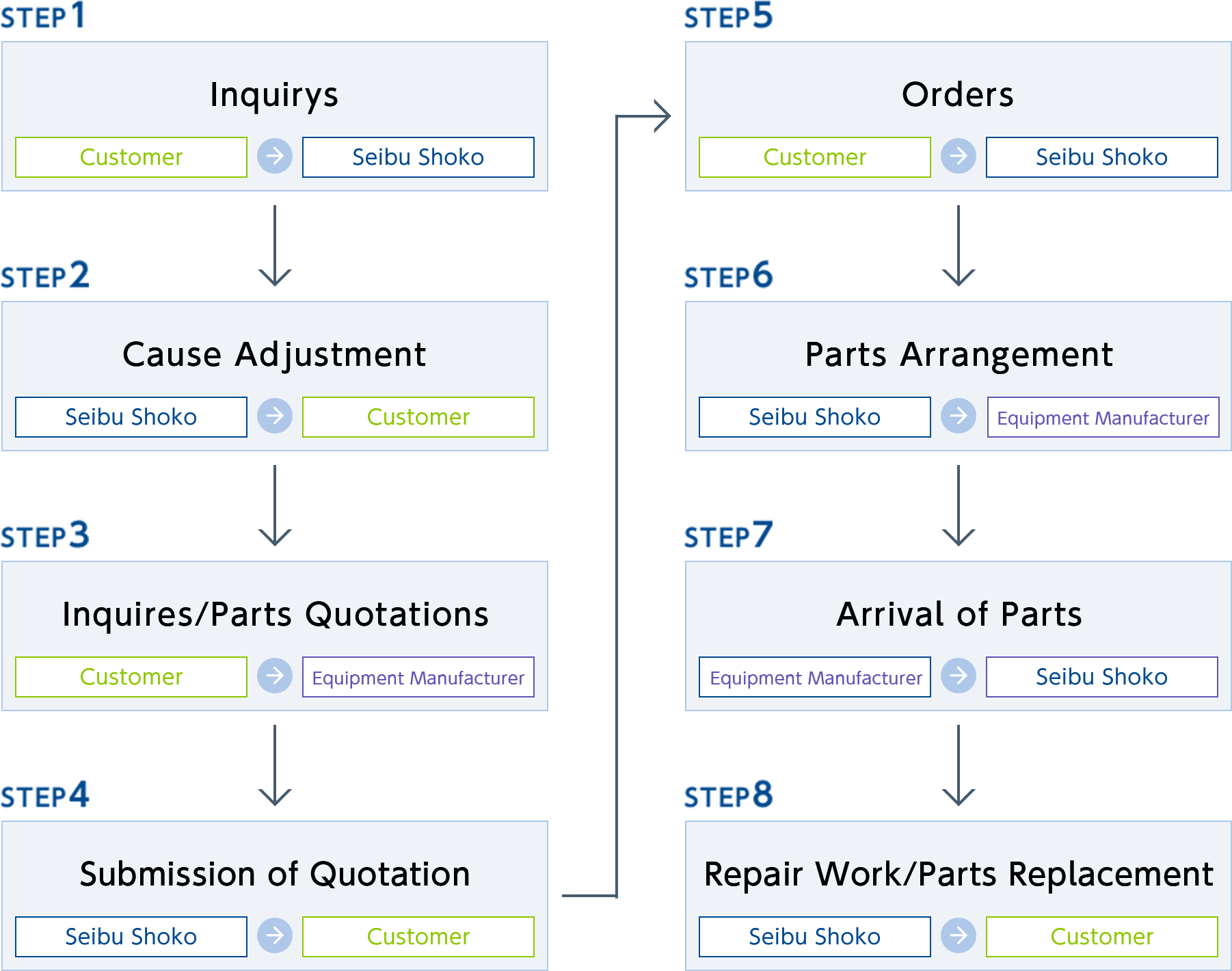

- What is the repair service flow for SIEMENS?

-

The repair service flow through Seibu Shoko is as follows.

- About Repair Costs

-

When we receive an inquiry about repair, we will first visit the site to investigate the cause of the problem. At a later date, we will provide an estimate of the cost of repair. After receiving a formal order for repair, we will arrange for parts, etc. (if necessary) and visit the site again at a later date to perform the repair work.

A basic business trip fee* is required for on-site investigation visits. If repairs can be made on the same day as investigation visit, a separate charge for labor and, if necessary, tooling and replacement parts will be incurred. (If repairs are made on a separate day from the investigation visit, the basic business trip fee and the cost of labor, tools, and replacement parts for repairs will be charged separately).

There may be cases where the equipment is working fine on the day of visit and diagnosis is not possible, or when repair is not possible as a result of the investigation. Please note that the basic business trip fee will still be incurred in such cases.

*Basic business trip fee (transportation, travel restraints, lodging, and business trip expenses)

- About Operation Checks After a Repair

-

After repair work is completed, our engineers will check the operation of the equipment. When all necessary operation checks, adjustments, and tests have been completed after the repair, the equipment is handed over to the customer."

System Proposal/Introduction Support

- Can the system be installed on any equipment?

-

Yes, it is possible to install the system regardless of the manufacturer. We will make the most appropriate proposal based on the existing equipment and design. There have been cases where lead time was significantly reduced, so please feel free to contact us even if you want an introduction to SIEMENS products but do not know which ones are suitable.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.