- English

- Japanese

- TEL

- 81-78-335-7573

DEBURR

- Models

- Overview

-

Planetary Deburring Machines including Precision Deburring

“Precision Deburring” is a technology to not only remove the burr, but to do so in a way that the edge breaks into a specified radius. This is critical for certain components, such as Fuel Injection parts, pump parts, Compressor Plates and sintered parts.

Gear Deburring Machines including Advanced Gear Chamfer Deburr

Grind Master Gear Deburring Machines include basic gear deburr machines using grinding wheels/brushes in a floating configuration for General Engineering industry.

Further Advanced Gear Chamfering-Deburring machines using Cold Forming Technology are for Automotive Powertrain gears. - Applications

-

・Deburring of punched fine blanked, laser and plasma cut parts

・Precision deburring of sintered parts, pump parts and fuel injection parts

・Deburring of punched and fine blanked parts like clutch plates and deburring of compressor plates

・Deburring of all kinds of gears – Spur, Helical and Bewel gears

・Deburring of sprockets (where chamfer is allowed on the sprocket teeth)

・Deburring of wheel gear

・Deburring Crown wheel

・Deburring of shaft gears

・Deburring and chamfering of gears with uniform chamfer

・Deburring & finishing of batch production sheet metal parts

・Deburring punched and nibbled sheered parts

・Deburring of laser, plasma, flame and waterjet cut parts

・Deburring zintec, galvanised, aluzinc, plastic and film coated -parts without coating damage

・Deburring of Steering Gear Piston

・Deburring of Cam Lobes – 2 Wheeler/ 4 wheeler Camshafts

・Crank Pin Cross hole Deburring

・Engine Thrust Washer Deburring

・Precision deburring of flat parts

・Deburring of Housing Bearing

Movie

Models

PLANETARY DEBURRING MACHINES

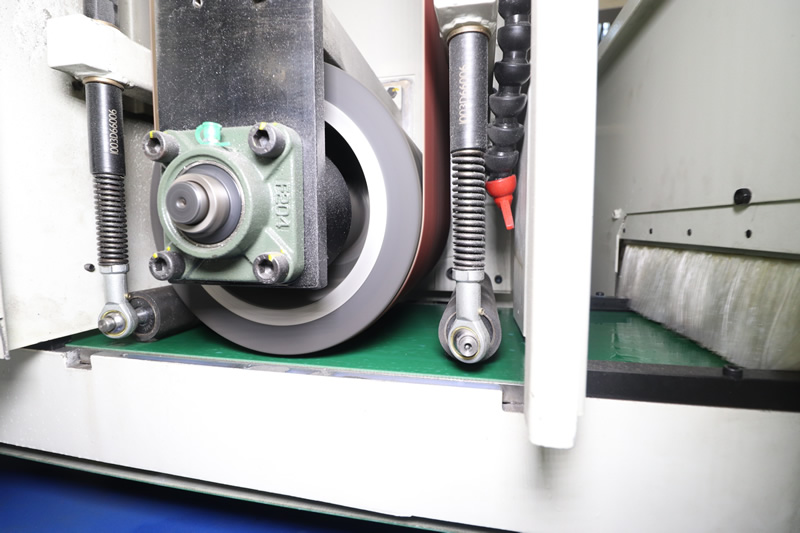

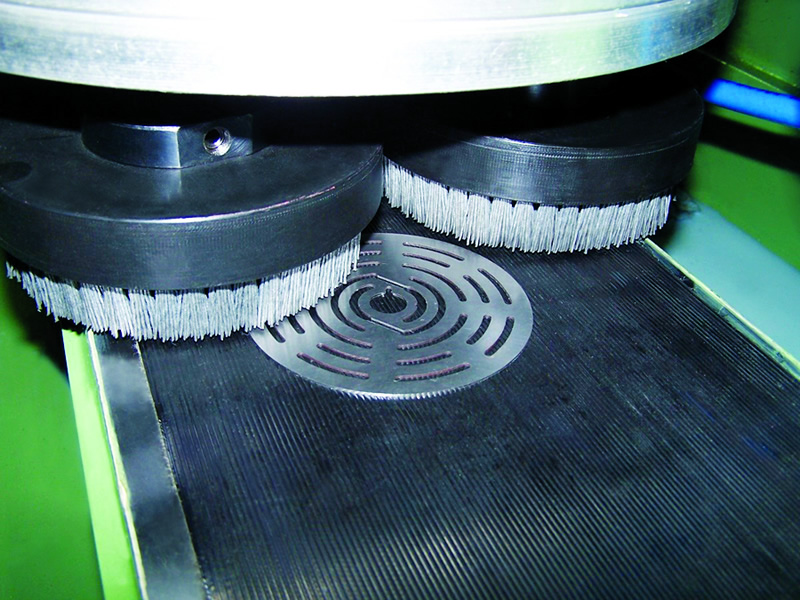

Planetary Deburring Machines use planetary head which accommodates independent rotating brush heads in it. The individual rotation of brush heads along with rotation of complete head results in burr removal from every corner of the profile. The CF Series of Machines includes combinations of Planetary Deburring and Belt Grinding Technologies, for removing coarser burrs. One variant of CF series called “PPDH” is used for Precision Deburring and can achieve micro radius on critical parts.

Applications

・Deburring of Clutch parts

・Deburring of Fine Blanked parts

・Deburring of punched parts

・Deburring of Laser cut parts

・Deburring of brake pad parts

・Deburring of sintered parts

・Deburring of hydraulic pump parts

GEAR DEBURRING MACHINES

Gears are major component of most of the mechanical assemblies. It performs important task of transmitting power from one mechanical part to another with desired RPM and torque as per process requirement. The chamfering and deburring of gears is often an undervalued process in gear production. However, it has a great influence on the usage characteristics of the work piece. Improvements in ratings for gear shifting in vehicles also depends on the process used for this operation. Reliable and good quality chamfering and deburring of gears ensures:

1. Longer Life

2. Lower Noise

3. Smoother shifting of gears

4. Lesser Failure/breakdown of geared parts

Gear deburring machine offered by Grind Master is used by various industry to deburr gear teeth after machining process. It uses grinding wheels, carbide burr tools and abrasive brushes to remove the burr efficiently with the tool floating mechnism and wih options like -

・Auto Job Load/ Unload

・Dust Extraction System

Applications

・Deburring of all kinds of gears – Spur, Helical, Bewel gears

・Deburring of sprockets

・Deburring of wheel gears

・Deburring of Crown wheels/ Bevel gears

・Deburring of shaft gears

SPECIAL PURPOSE DEBURRING MACHINES

Grind Master Special Purpose Deburring Machines are custom engineered for meeting specific component requirements. The deburring is done by special abrasive nylon bristle wheels and coated abrasive belts. The deburring is mostly done after precision grinding process to remove the grinding burrs.

Machine Model / Description

CDB Series

1. Complete Reliable Cam Lobe Deburring Machine

2. Productivity : Upto 2 Jobs / min

CFG_Platen_PLC

1. Platen Type Belt Grinding Machine

Productivity : 20 to 25 Components / min

Crank Pin Deburring

1. Crank Pin Deburring SPM with Auto Reverse mechanism

2. Productivity : 10 to 20 Jobs / min

Applications

・Deburring of Steering Gear Piston

・Deburring of Cam Lobes – 2 Wheeler / 4 wheeler Camshafts

・Crank Pin Cross hole Deburring

・Engine Thrust Washer Deburring

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.