- English

- Japanese

- TEL

- 81-78-335-7573

SUPERFINISHING MACHINES

- Models

- Overview

-

Grind Master NANOFINISH Machines are based on a modular design concept, and can be optimized for specific applications with configurable stations including no. of arms, Arm positioning mechanisms and Automation Systems and Peripheral Systems. Optional additions include Deburring Units. The Machines are controlled with an Engineered Software NANOFINISH Control System built for finishing machines.

The state of the art range of machines NF Series are packed with several features that make them a market winner. Optimized Cycle times, Quick Setup Change, Quick Tooling Change, Ease of Maintenance are some of these.

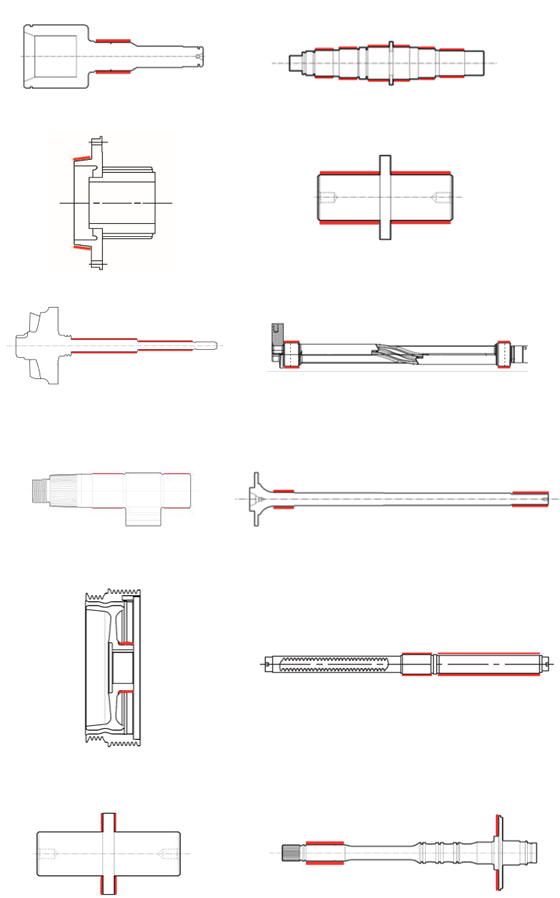

Superfinishing Machine uses the head consisting of Film Backed Abrasives stretched around contact wheel oscillated against the work piece which is held between centres. This process is useful to generate surface finish Upto Ra 0.05 - Applications

-

・Superfinishing of Automotive Transmission Parts

・Synchro Cone, Idle Gears, Armature Shaft, Stepped Shaft,Turbo Charger Shaft, Transmission Yoke and Output Shaft,

・Superfinishing of Gear Pump Shafts

・Superfinishing of Piston Pins, Cam follower, Piston Rods, Brake ・Pistons and Vacuum Pistons

・Superfinishing & Chrome Polishing of Rotogravure Cylinders

・Superfinishing/Polishing of Steering Rack Bars

・Superfinishing of Heavy Diesel Engine Pins

・Specialized Superfinishing Applications in Aerospace

・Superfinishing of Flat surfaces of Gear Pump Shaft, Main Shaft, Balancer Shaft and Turbine Shaft

・Internal Superfinishing

・Centreless Throughfeed Superfinishing for Pin Type Components

Models

SMP 500E

・Admit Between Centre 500 mm

・International Built Standard

・Optional – GSF Size Control Technology

・Expandable to Multiple Stations with Automation

・Grind Master NANOSMART Industrie 4.0 Enabled Controller

・Grind Master NANOFINISH Control System

・Modular Design – Compact, Energy Saving & Ultra User Friendly

・Optimised cycle times

・Quick Setup Change

・Quick Consumable Change

・These Machines are Customized to meet specific Customer Needs of Automation, Load/Unload, Size and many more.

SMP 1000 Series

・Admit Between Centre 1000 mm

・Grind Master NANOSMART Industrie 4.0 Enabled Controller

・Grind Master NANOFINISH Control System

・Modular Design – Compact, Energy Saving & Ultra User Friendly

・Optimised cycle times

・Quick Setup Change

・Quick Consumable Change

・These Machines are Customized to meet specific Customer Needs of Automation, Load/Unload, Size and many more.

CST

・Centreless Throughfeed Superfinishing

・Grind Master NANOSMART Industrie 4.0 Enabled Controller

・Grind Master NANOFINISH Control System

・Modular Design – Compact, Energy Saving & Ultra User Friendly

・Optimised cycle times

・Quick Setup Change

・Quick Consumable Change

・These Machines are Customized to meet specific Customer Needs of Automation, Load/Unload, Size and many more.

SMT Series

・Flat Surface Superfinishing

・Grind Master NANOSMART Industrie 4.0 Enabled Controller

・Grind Master NANOFINISH Control System

・Modular Design – Compact, Energy Saving & Ultra User Friendly

・Optimised cycle times

・Quick Setup Change

・Quick Consumable Change

・These Machines are Customized to meet specific Customer Needs of Automation, Load/Unload, Size and many more.

SMI Series

・Internal Superfinishing

・Grind Master NANOSMART Industrie 4.0 Enabled Controller

・Grind Master NANOFINISH Control System

・Modular Design – Compact, Energy Saving & Ultra User Friendly

・Optimised cycle times

・Quick Setup Change

・Quick Consumable Change

・These Machines are Customized to meet specific Customer Needs of Automation, Load/Unload, Size and many more.

Specs

| SMP 500E | SMP1000 Series | |

| Range length of workpiece (mm) | 500 | 1000 |

| Range of O.D of workpiece (Φmm) | 75 | 75 |

| Range width of film (mm) | 200 | 200 |

| Max swing diameter (mm) | 150 | 150 |

| Output Ra Finish (μm Ra) | 0.1~0.4 | 0.1~0.4 |

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.