- English

- Japanese

- TEL

- 81-78-335-7573

SEARCH

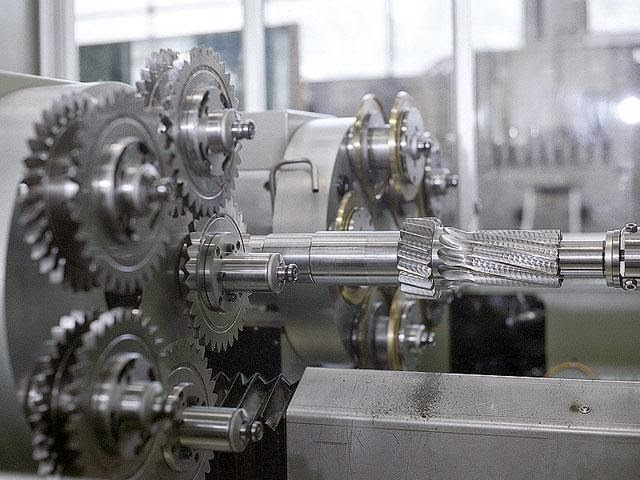

CDX 250 H Chamfer/Deburr Machine

- Overview

-

The CDX 250 is engineered with 2 tool slides, each mounting a rotating tool revolver. Each revolver can assemble up to 5 different tool heads, meaning that it is possible to have 10 different tool groups readily available at all times! Thanks to this innovative design concept, it is possible to work shafts with up to 5 different gearings or different families of gears and shafts, at the same time or one after the other, without having to reset machine parameters or change tools (provided that the same clamping can be used).

Setting up and operating the machine is aided by a user-friendly operator interface with onscreen operator guidance. Optionally, the CDX 250 can also be equipped with a drilling unit to apply coolant holes to workpieces. To prevent drill breakage, an integrated phasing unit can be supplied to ensure that drills are positioned correctly, and an automatic drill tool inspection unit is also available to monitor drill condition. The CDX 250 can be adapted to suit many different automation systems.

・Chamfering and deburring of gears and shafts

・2 revolving drums, up to 10 tool heads

・Up to 5 different gears in one setup

・Different tool types available

・Minimum tool change requirements during production

・Minimum setup requirement during production

・Integrated centering unit (option)

・Integrated drilling unit for lubrication holes (option)

・Different automation and workpiece storage

・solutions

Specs

| Technical Data | Units | CDX 250 H |

|---|---|---|

| Workpiece diameter, max. | mm | 250 |

| Module, max. | mm | 5.0 |

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.