- English

- Japanese

- TEL

- 81-78-335-7573

Your Japan Service & Repair Team

We work with many of the world’s class names in Japan Manufacturing industry to develop our service & repair services.

Combination of Mechanical skill and Customer Relation skill

Our pool of knowledge surrounding machine tool performance and accuracy is superior quality. This skill base gives us a competitive edge which is reflected in the high level of service we provides to our clients. We’re not just a service provider; we pro-actively works with clients to develop tailor-made solutions for both generic and unique technical problems.

The long-term relationships that this engenders results in a much greater understanding of a customer’s needs. This in turn ensures that Seibu Shoko delivers the optimum service package; providing repair, training and maintenance support.

-

Corrective Maintenance

-

Preventive Maintenance

-

Predictive Maintenance

Diverse Team

Our team are consists of various background of countries and skills. We can deliver our services in Japanese, English, Bahasa Indonesia and Bahasa Malaysia. Also we are now exploring for Thai and Vietnamese.

Total Package of Services

We offer not only service & repair program, but also with spare parts preparation and management. This helps our client to minimize the amount of capital blocked in inventory while ensuring the timely availability of spare parts.

Reliability Centered Services

We refer to the machine OEM itself as much as possible to maintain the original machine functions and operation. This may include replacement, redesigning or even decommissioning of the machine tool.

Approved Partner of Siemens

Seibu Shoko are proud of our accreditation as an official partner for Siemens. Before accepting companies as partners, Siemens ensure that we must prove our capabilities. Only then do Siemens certify Optima according to rigorous, globally uniform standards, systematically supporting and enhancing us using the same criteria Siemens apply to the training of their own employees.

Our Skills

PLC/CNC & Electrical Unit

PLC/NC devices play a crucial role in controlling machine tools. Please consult us for any issues or concerns regarding PLC/NC devices. Our company has specialized engineers in PLC/NC systems who can respond to emergency requests.

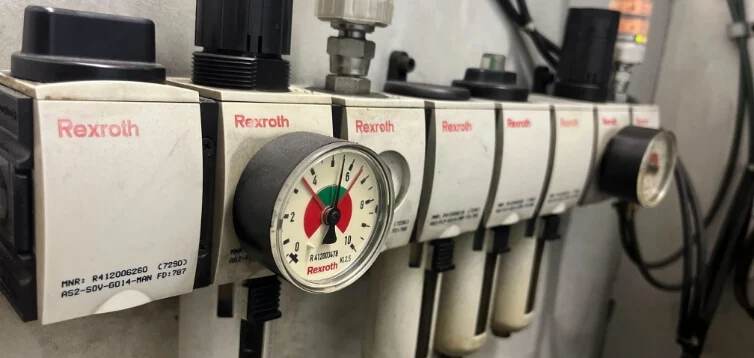

Pneumatic Unit

We provide comprehensive support from compressor malfunctions to filter replacements. We can handle machine equipment from overseas manufacturers and arrange for parts accordingly.

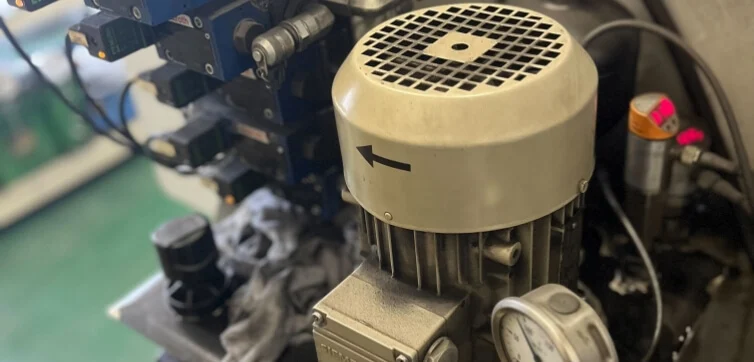

Hydraulic Unit

We can repair pump malfunctions and replace parts such as hoses, valves, and accumulators. We also handle machine equipment from overseas manufacturers and arrange for parts as needed.

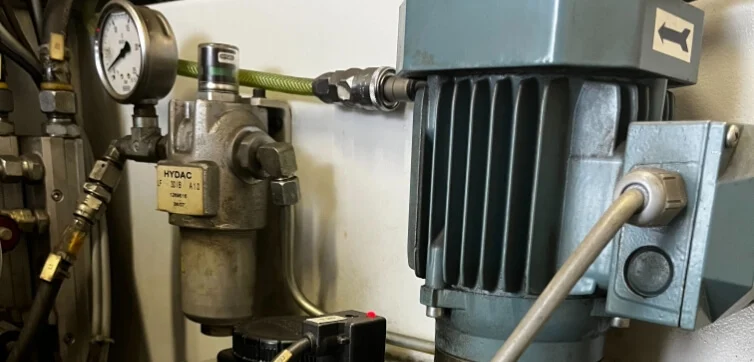

Lubrication Unit

We can perform lubrication-related parts replacements and repairs, including motors, tanks, pumps, and filters. We handle machine equipment from both domestic and overseas manufacturers and arrange for parts as needed.

Cooling Unit

We can support equipment from overseas manufacturers like Knoll and Hoffmann. Additionally, by entering a maintenance contract, we can ensure preventive maintenance to maximize machine efficiency, giving you peace of mind.

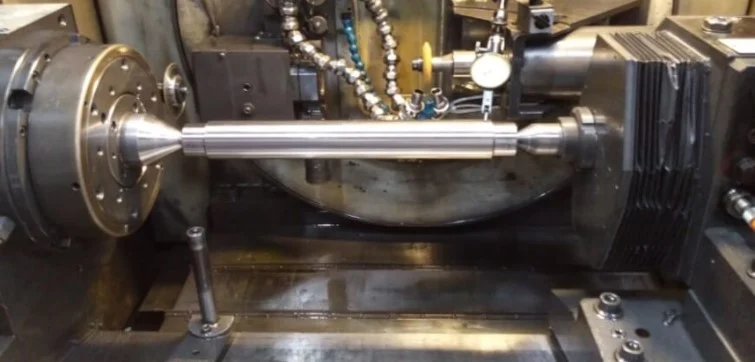

Mechanical

We can address issues with machine unit components such as spindles, tailstocks, and dressers. We can also communicate in English and propose solutions from overseas manufacturers based on your needs. Parts arrangement can also be handled as part of our services.

Machine Relocation

Our company offers comprehensive machine relocation services, including disassembly, transportation, and reassembly at the new location

Retrofit

Our retrofit services include upgrading control systems, adding new features, improving automation, and integrating advanced components to optimize machine functionality.

Maintenance Training

Customized training programs can be developed to address specific equipment types and client needs, enhancing operational efficiency and reducing downtime.

Frequently Asked Questions

We lost a lot of drawings and documents. Will you still help us?

Drawings and documents are one of the many tools that important to a machine tool. However, before you giving up, lets have a discussion! We will think a way for you.

Our team don't speak Japanese/English

Our engineer team able to communicate in Japanese, English, Bahasa Melayu and Bahasa Indonesia. We also have a team dedicated to interpreting services for Vietnamese and Thai. Fell free to contact us if you would like to request other languages.

My machine is more than 20 years old and the OEM itself does not exist anymore.

Usually, for an old machine, we would recommend for a retrofitting. It is because retrofitting provides ability to revitalize the machine with new controls, thus giving the machine a longer service lift.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.