- English

- Japanese

- TEL

- 81-78-335-7573

Cutting tools

- Hobs

- Milling Cutters

- Chamfer & Deburring Tools

- Gear Shaving Cutters

- Master Gears, Ring and Plug Gauges

- Gear Shaper Cutters

- Scudding®

- Gundrills

- Carbide Drills & Reamers

- PCD Tooling

- Carbide Blanks & Preforms

Hobs

-

Involute Gear Hobs

Star SU provides a large variety of involute gear hobs including single thread, multiple thread, involute spline, worm gear heads, and solid carbide hobs.

-

Non-Involute Gear Hobs

Star SU Non-Involute Gear Hob offerings include sprocket, straight key spline, and special form hobs.

-

Customized Hob Shapes

Customized Hob Shapes can be designed and manufactured to your exact specifications. We provide custom special drive hobs and shank hobs.

Milling Cutters

-

Single and Duplex Milling Cutters

Single and duplex milling cutters are available for most tooth forms from standard involutes and sprockets to special splines and worm cutters.

-

Saw Blade Milling Cutters

Saw blade milling cutters for hack, band, or circular saw blades come in single or variable pitch, straight or tapered outside diameters, single cutters up to 13.5” long or interlocked sets, accurate unground or hard finished.

-

Multiple Thread Milling Cutters

Availble in shell type or shank type, multiple thread milling cutters are form relieved and can be supplied with special thread forms.

-

Special Form Milling Cutters

Special Form cutters are manufactured in a wide range of configurations, including straight and spiral gash designs for cutting gear racks; serration form cutters for chuck jaws and steering gear segments as well as a wide variety of special form relieved cutters for producing items such as pliers, clipper guides, concave and convex form, and tool bits. The drives range from simple keyway bores to complex hubs and shanks.

-

Rack Milling Tools

Star SU provides unparalleled quality for multiple pitched form relieved milling cutters from standard rack forms to asymmetrical shapes. Metric or inch dimensions up to 300mm long. We offer you a high quality, competitive cost and delivery alternative as a manufacturer of Rack Milling Cutters made to your specific manufacturing needs.

Chamfer & Deburring Tools

-

Chamfering Tools

Chamfering the flank edges of spur and helical cylindrical gears prevents edge distortion during heat treatment and protects the tooth profile against any nicks that may occur during handling.

-

Deburring Tools

A burr which is not removed may break off during use and damage bearings or gears in gearboxes.

Over-carbonizing may result in too much pressure being exerted on sharp gear lateral surfaces which might then break. A hardened burr may lead to premature wear of tools in subsequent finishing operations. Removal of very sharp burrs reduces the risk of tool handling injuries. -

Chamfer, Deburr & Rolling Tools Combos

Chamfer, deburring and rolling tools are available as combination tools in set of various combinations.

Gear Shaving Cutters

Master Gears, Ring and Plug Gauges

Gear Shaper Cutters

Scudding®

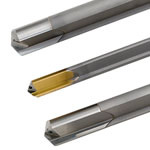

Gundrills

-

Single Flute Gundrills

The single flute gundrill, with its ability to machine very straight deep holes and hold excellent finishes, was originally developed for gun barrel manufacturing. Today, this drill is designed for deep hole drilling in virtually any material.

-

Solid Carbide Single Flute Gundrills

Solid carbide gundrills have a two-piece construction design. The tip and body are a single piece of carbide brazed into the driver/shank and the flute is ground down the length of the head and body. This rigid design has made its way into CNC machining centers and lathes, equipped with high pressure coolant delivery systems.

-

Two-Flute Two-Hole Gundrills

Often referred to as the “milled style,” the two-flute two-hole gundrill differs from the double crimp by the rigidity of its body. This rigid body allows for higher feed rates than traditional crimp body style drills.

-

Double Jet Gundrills

Star SU, with its years of experience in gundrilling developed a Star original patented Double Jet Gundrill. The most critical interface, in which the carbide is subjected to the most traumas, is during entry/exit of the part and during interruptions of the boring cycle.

-

Double Crimp Gundrills

The term double crimp is derived from the process of crimping the same tube used for the single flute gundrill, only crimping it twice, 180 degrees apart. Therefore, with the flute channels on this type of tool being somewhat shallower then the single flute, they limit the type of materials to be drilled by the chip size generated.

-

Bi-Tip Gundrills

Similar to the Two-Flute Two-Hole “milled style” product line engineered with a solid steel body, the Bi-Tip has an auger-like helix ground in the body.

Carbide Drills & Reamers

-

Multi Diameter Cavity Machining Tools

Star SU has perfected a line of cavity/porting tools that will allow cuts from either a solid or cast core casting condition. In many cases, these multi-step tools will allow cavity machining in one pass or shot.

-

Solid Carbide Drills

Star SU's specially designed, solid carbide drills are available as straight or helical drills, single or multiple diameters drills, single or multiple-flute design, diameter range starting from 0.1875" (4.76 mm).

-

Solid Carbide Core Drills

Star SU has special design and build core drills that are ideal for machining aluminum, ductil, nodular, and compacted graphite irons (CJI).

-

Reamers

Star SU reamers are made in both multiple flute and multi-diameter types. Based on the overall length of the tool required to machine your feature, we can manufacture a solid carbide reamer or braze a solid carbide reamer head to a tubular steel body.

-

Super Round Tool (SRT)

Super Round Tool (SRT) Lead InThe SRT is an original Star Cutter Company design and build product that offers a unique, patented design that combines two tools into one — multiple straight flutes for consistent location and multiple helical flutes to ensure roundness and finish.

-

Valve Guide Reamers

Star SU valve guide reamers utilize pressurized coolant to force chips ahead of the tool to produce ultra-smooth, ultraprecise holes. They produce holes to tolerance of 0.0005" (0.13 mm) and less in steel, cast iron, compacted graphite iron, nodular iron, aluminum, bronze and exotic materials.

PCD Tooling

-

PCD Precision Reamers

Star SU/Neher designs and builds precision helical and straight flute PCD reamers, available in carbide and steel body monoblock styles. All tools are manufactured specifically to meet custom design requirements.

-

PCD Deep Pocket Side Mill

Our special designed combination PCD Deep Pocket Side Mills feature coolant holes sized and placed for optimal performance.

-

PCD Combination Tooling

Star SU/Neher engineers and manufactures high quality PCD combination tools designed to meet or exceed custom requirements.

-

PCD Milling Cutters

Fixed Pocket Milling Cutters are engineered to machine both high and low silicon aluminum. Our standard and special design cutters allow for the maximum number of cutting teeth compared to indexable cutters allowing for reduced cycle times.

Carbide Blanks & Preforms

-

Carbide Drill & Reamer Blanks

Using both CNC and manual equipment H.B. Carbide can provide detailed special preforms with minimal grind stock to your print.

-

Specialty Blanks

Blanks can be manufactured for your specific requirements using any of the grades we offer. Our experienced operators, using CNC and manual equipment, can manufacture nearly any blank you require.

-

Carbide Die Blanks

Die blanks are available in multiple grades for die nibs, drill bushings, valve trim, chokes and more.

-

Special Extrusions

Star SU carries the following standard extruded products in most H.B. Carbide grades.

-

Round Rod

H.B. Carbide manufactures several types of round rod in numerous sizes and multiple grades including round rods, single hole rods, two-hole rods, ground round rods, and helical hole rods.

-

Gundrill Blanks

Standard gundrill extrusions up to 12.2” long are available in diameters ranging from 0.098” to 0.770” OD and are available with three different coolant hole geometries.

-

Flat Blanks

Flat blanks are available from H.B. Carbide in all carbide grades. They can be used for wire EDM, knife blanks, form tools, rings, and washers.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.