- English

- Japanese

- TEL

- 81-78-335-7573

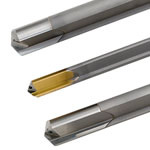

Single Flute Gundrills

- Overview

-

The single flute gundrill, with its ability to machine very straight deep holes and hold excellent finishes, was originally developed for gun barrel manufacturing. Today, this drill is designed for deep hole drilling in virtually any material.

The gundrill requires high-pressure coolant through the tool, keeping the cutting edges lubricated and providing adequate chip evacuation down the flute channel. Star SU’s Single flute gundrill product line diameter range is .039” [1.00mm] through 1.500” [38.10mm] as a solid carbide head.

Larger diameter tools are available using a brazed inserted blade design. All gundrills can be made to any specific length. Lengths over 72” [1828 mm] will have an additional weld joint in the body of the tool.

The gundrill is designed to drill holes from solid material, and can produce bottom hole configurations, and minimize burr at intersections. The gundrill can achieve precision holes in one pass thus eliminating the need for secondary passes, and is a tool for consistent hole-to-hole reproduction.

The design of the single-lip, straight deep “V” flutes and high coolant pressure allows for fast, consistent penetration without the need for pecking.

Due to the point not being on center, the tool requires either a bushing or a pilot hole starting support. Once into the cut, the tool is self-piloting. The additional advantages of a single flute gundrill:

・Straightness tolerance of .001” [0.03mm] per inch

・Finish hole diameters as good as +/- .0005” [0.013mm]

Star offers three different styles of coolant hole configurations:

Kidney Shaped Hole (KDS)

This style is recommended for cutting diameters under .375" [9,53mm]. This extruded shape assists in achieving higher flow out of the front of the tool, thus allowing for better chip evacuation. This coolant hole configuration also can assist when lubricity is minimal.

Single hole (GDS)

This provides maximum strength to the carbide head, for challenging applications.

Dual Hole Configuration (TCH)

This coolant hole design is recommended for cutting diameters .376" [9,54mm] and greater. This design allows for higher flows assisting in better chip evacuation and the ability to direct flow to needed areas during the sharpening process.

Gundrills

-

Single Flute Gundrills

The single flute gundrill, with its ability to machine very straight deep holes and hold excellent finishes, was originally developed for gun barrel manufacturing. Today, this drill is designed for deep hole drilling in virtually any material.

-

Solid Carbide Single Flute Gundrills

Solid carbide gundrills have a two-piece construction design. The tip and body are a single piece of carbide brazed into the driver/shank and the flute is ground down the length of the head and body. This rigid design has made its way into CNC machining centers and lathes, equipped with high pressure coolant delivery systems.

-

Two-Flute Two-Hole Gundrills

Often referred to as the “milled style,” the two-flute two-hole gundrill differs from the double crimp by the rigidity of its body. This rigid body allows for higher feed rates than traditional crimp body style drills.

-

Double Jet Gundrills

Star SU, with its years of experience in gundrilling developed a Star original patented Double Jet Gundrill. The most critical interface, in which the carbide is subjected to the most traumas, is during entry/exit of the part and during interruptions of the boring cycle.

-

Double Crimp Gundrills

The term double crimp is derived from the process of crimping the same tube used for the single flute gundrill, only crimping it twice, 180 degrees apart. Therefore, with the flute channels on this type of tool being somewhat shallower then the single flute, they limit the type of materials to be drilled by the chip size generated.

-

Bi-Tip Gundrills

Similar to the Two-Flute Two-Hole “milled style” product line engineered with a solid steel body, the Bi-Tip has an auger-like helix ground in the body.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.