- English

- Japanese

- TEL

- 81-78-335-7573

SEARCH

MICROFINISHING MACHINES

- Models

- Overview

-

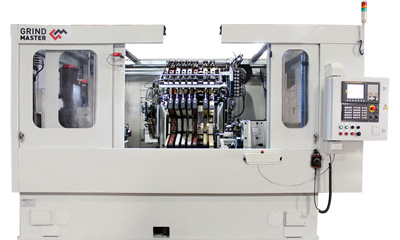

Grind Master NANOFINISH Machines are based on a modular design concept, and can be optimized for specific applications with configurable stations including no. of arms, Arm positioning mechanisms and Automation Systems and Peripheral Systems. Optional additions include Deburring Units. The Machines are controlled with an Engineered Software NANOFINISH Control System built for finishing machines.

The state of the art range of machines NF Series are packed with several features that make them a market winner. Optimized Cycle times, Quick Setup Change, Quick Tooling Change, Ease of Maintenance are some of these.

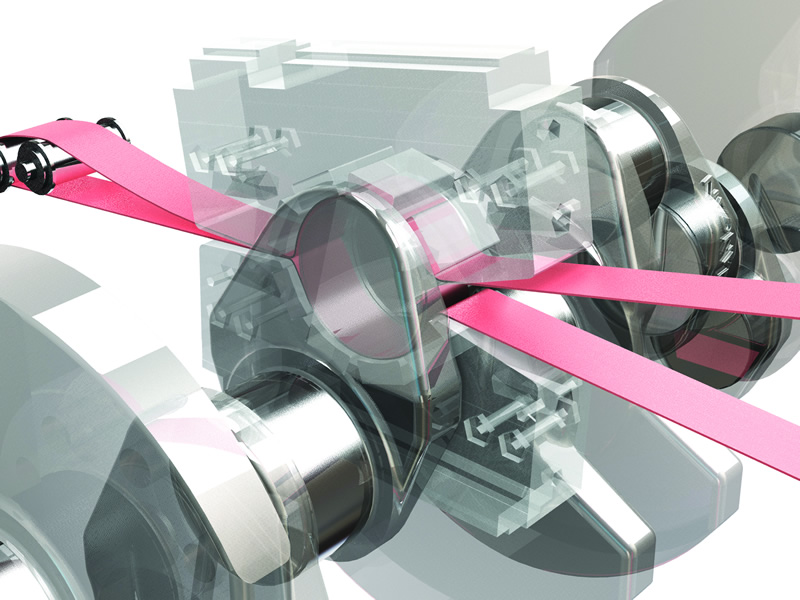

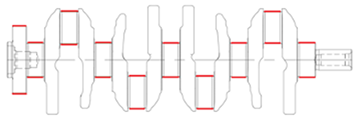

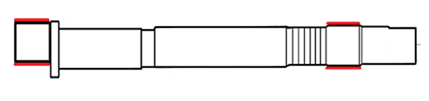

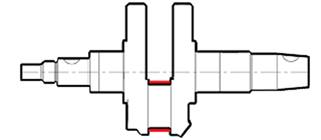

Microfinishing Machine uses the head consisting of Film Backed Abrasives with Shoe-Type Backing which covers the work piece such as crankshaft/ camshaft which is oscillated between centers. The process also achieves improvement in geometrical parameters such as roundness. - Applications

-

・Microfinishing of Crankshafts : 200mm to 3.5 metres size

・Microfinishing of Camshafts : 75mm to 2.5 metres size

Work Example

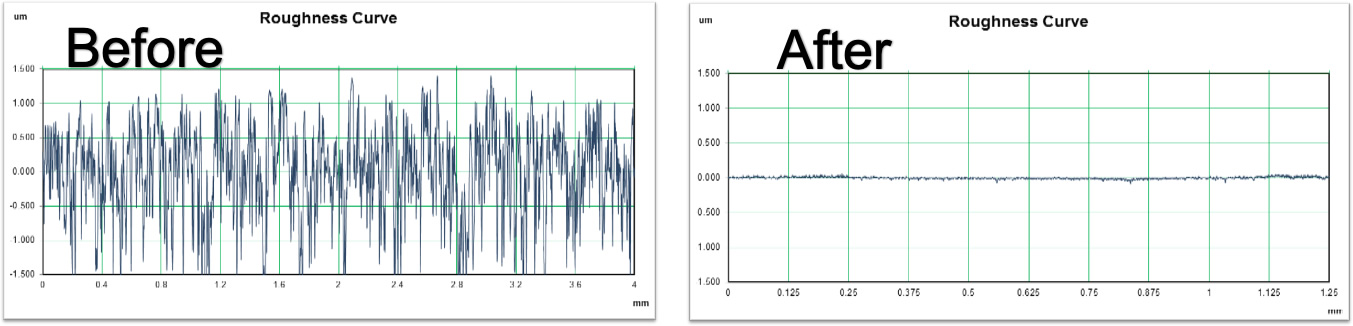

Pin and Main Journal:

Input– 0.5 μm Ra

Output– Rk 0.34, Rpk 0.12,

Oil Seal Diameter :

Input– 0.6 μm Ra

Output– 0.25 Ra

Cycle time – 75 sec

Input– 1.5 μm Rz

Output– 0.3 μm Rz

Cycle time – 20 sec

Input– 2.5 μm Rz

Output– 1.5 μm Rz

Cycle time – 50 sec

Movie

Models

NF300Cr

・Admit Between Centre 300 mm

・Crankshaft Microfinishing Machine

・For Single Cylinder Engine Crankshafts

NF600Cr

・Admit Between Centre 600 mm

・Crankshaft Microfinishing Machine

・NEXT GEN Flexible Compact Machine

Specs

| NF300Cr | NF600Cr | |

| MaximumCrankshaftLength(mm) | 70-300 | 350-600 |

| MaximumMicrofinishLength(mm) | 300 | 600 |

| Maximum Swing(mm) | 120 | 210 |

| Maximum Throw (Crankshafts)(mm) | 35 | 65 |

| Minimum Bearing C/L to C/L(mm) | 40 | 37.5 |

| Maximum Bearing Diameter(mm) | 46 | 85 |

| Machine Dimension | 3.5 L X 2 W X 2.1 H | 4.3 L X 4.5 W X 2.25 H |

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.