- English

- Japanese

- TEL

- 81-78-335-7573

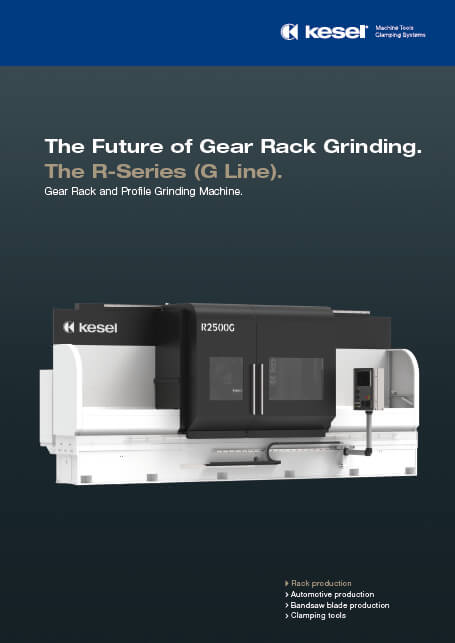

THE R Series Rack Grinding Machines (G Line)

- Overview

-

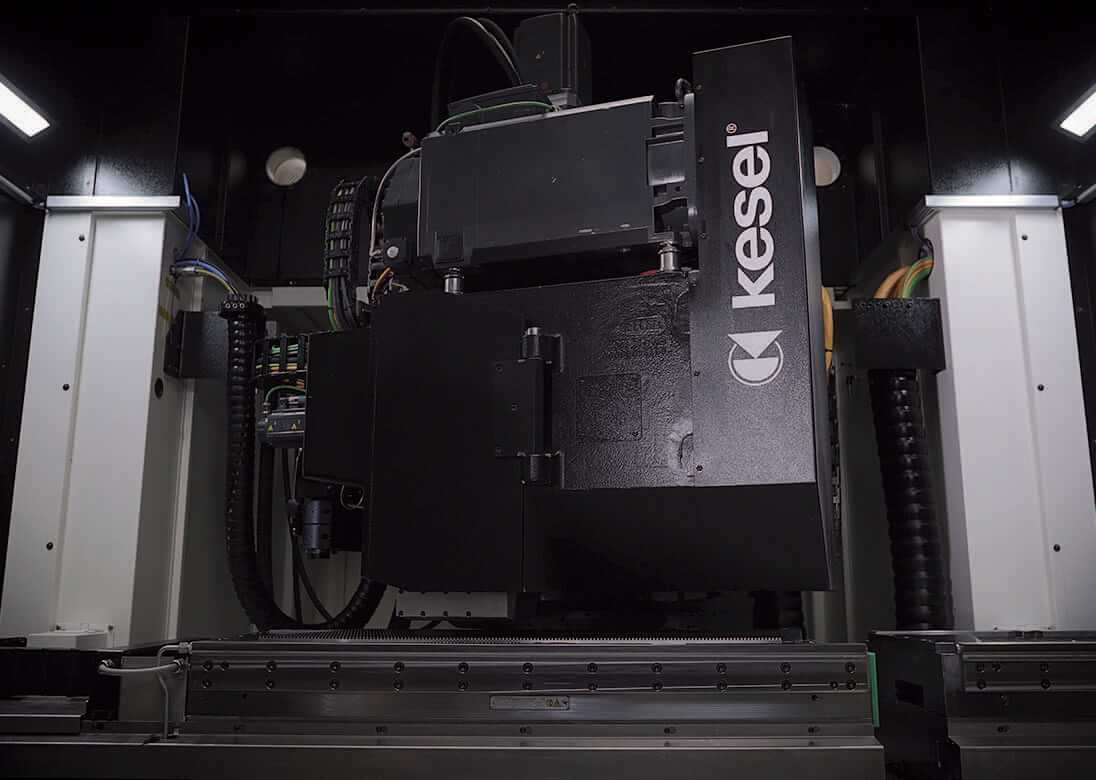

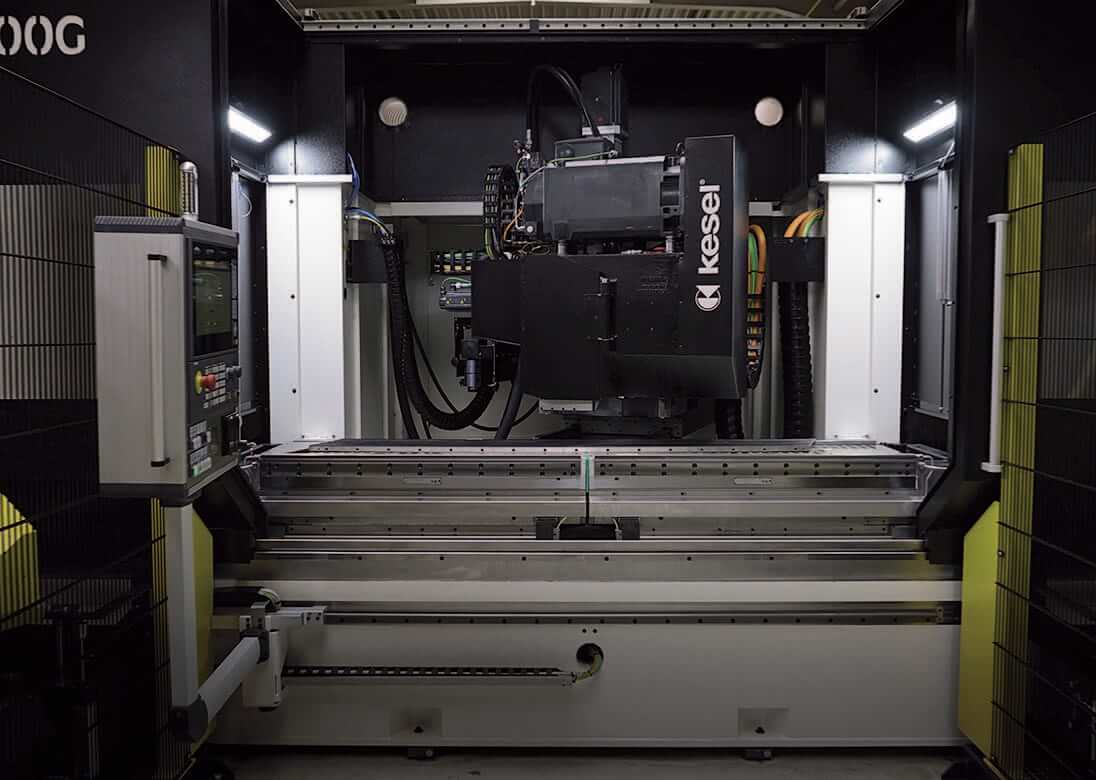

With a brand new design and extensively optimised high-performance technology, he R Series grinding machines from Kesel set a new standard in high quality, high roductivity gear rack and profile grinding. From the newly developed grinding head to he re-engineered coolant and swarf management system, the R Series machines eliver both industry-leading dimensional precision and unbeatable surface quality.

Looking for more productivity? The world-first X2T table setup, an integrated swarf vacuum system and the option to fully automate the machine ensure there are multiple options and methods to deliver a winning competitive edge.

The R Series grinding machines from Kesel. The next generation of rack and profile grinding.

Features

Grinding

The S98 grinding head delivers maximum power across the full 127 mm maximum width of the grinding surface. With an integrated and automatic balancing unit the S98 is not only hugely powerful but maintains absolute precision at all times.

The new compact design has been engineered to minimise maintenance requirements whilst increasing positioning accuracy.

The air-cooled dressing spindle on the S98 achieves a reduced energy consumption during dressing whilst maintaining its market-leading precision. With grinding wheels up to a maximum width of 127 mm and 400 mm in diameter, the R Series delivers high-productivity whilst maximising the wheel’s usable diameter.

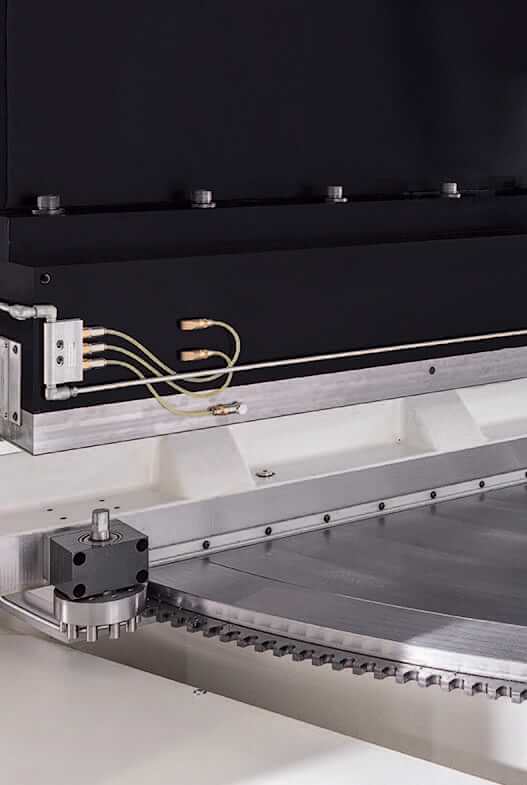

X2T Twin-Table System

As well as the conventional, single table setup, the R-Series is also available with the world-first X2T twin-table system. The X2T comprises of 2 tables, each of which is capable of holding racks half the length of the machine’s maximum capability. This system allows one table to be machined whilst concurrently the second table is loaded / unloaded. The result is up to 2.7 times more productivity! And should the machine’s maximum grinding length be required, the tables can be coupled in under 3 minutes for ultimate manufacturing flexibility.

B-Axis

Available as either a manual or fully automated axis, the R Series has a B-axis range of +/- 25°, allowing it to grind the full range of helical racks.

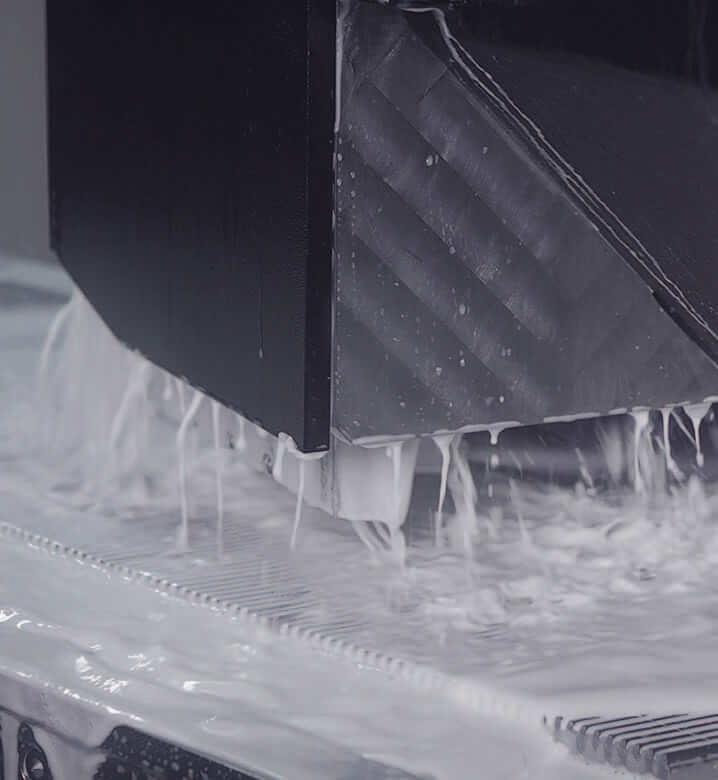

Coolant & Filtration Management

The intelligent coolant management system supplied with the R Series machines is fully automated to increase operation efficiency. Coolant volumes and pressures are continually monitored and maintained via the coolant unit’s control system which is fully integrated into the grinding machine’s operating architecture.

More complex coolant applications, such as volume and pressure changes during roughing and finish grinding can be easily programmed.

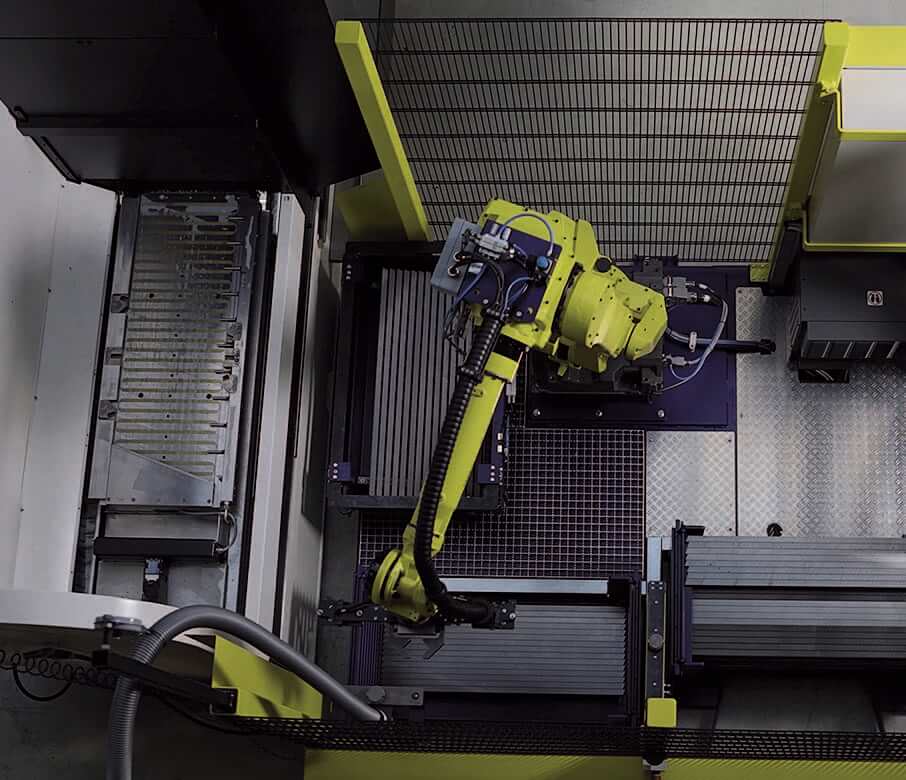

Automation

All models within the R-Series can be supplied with fully automated load / unload cells in order to allow frictionless machine operation with minimal operator influence. With an integrated cleaning system and magazine bays for easy and fast material access the R-Series automation is the perfect solution for maximising ROI.

Introduction Video

Specs

| Travel Range | ||

|---|---|---|

| 1 Table (*) | 2 Table (**) | |

| X1-axis (horizontal, table 1) | 2,940 mm | +/- 800 mm |

| X2-axis (horizontal, table 2) | +/- 800mm | |

| Y-axis (grinding head, vertical axis) | 238 mm | |

| Z-axis (feed axis, horizontal) | 610 mm | |

| B-axis (swivel axis/helical toothing) | +/- 25° | |

| Clamping area | 470 x 2,510 mm | 470 x 1,250 mm (2 x) |

(*) Table 1 and table 2 are coupled and driven by two linear drives.

(**) Table 1 and table 2 can be moved independently of each other with two drives per table.

| Travel Range – Dressing unit | |

|---|---|

| X32-axis (horizontal) | 136 mm |

| Y32-axis (vertical) | 120 mm |

| Travel Range Coolant Tracking | |

|---|---|

| Y33-axis | 115 mm |

| Grinding head | |

|---|---|

| Type | S98 |

| Power | 98 kW S1 |

| Grinding wheel adapter | Ø 152.4 mm / 6” |

| Grinding wheel diameter min. | 243 mm |

| Grinding wheel diameter max. | 400 mm |

| Grinding wheel width max. | 127 mm |

| Control |

|---|

| Siemens SINUMERIK ONE |

| Clamping system |

|---|

| Magnetic or hydraulic clamping system |

| Quality |

|---|

| Achievable tooth quality (To DIN 3962, part 1): Q5 |

| Coolant and swarf removal | |

|---|---|

| Cooling lubricant | Emulsion |

| Filling capacity | 6,500 Litre |

| Fine filtration | Band filter fleece |

| Integrated coolant monitor and management system | |

| Electrical connection | |

|---|---|

| Machine | |

| Voltage | 3 x 400 V |

| Nominal current | 200 A |

| Coolant unit | |

| Voltage | 3 x 400 V |

| Nominal current | 130 A |

| Dimensions and weight | ||

|---|---|---|

| Installation dimensions: | approx. L: 9,400 x D: 7,850 x H: 3,216 mm | |

| Machine weight: | approx. 28,500 kg | |

| Options |

|---|

| Automatic sliding doors |

| Controlled B-axis |

| Grinding wheel changing unit |

| Customised clamping setups |

| Coolant: Oil |

Additional accessories available upon request/Subject to modifications arising from technical advances

You can download the brochure.

The brochure, which includes detailed specifications, is available for free download.

Grinding

-

Generating Gear Grinding Machines

Generating Grinding machines feature simple design concepts and user friendly operation. The answer to your generating grinding needs is addressed by two main product families at Samputensili: The GT 500 H and G 250 / G 450.

-

Rotor and Worm Grinding

Perfected of the last 20 years, Samputensili rotor grinding machines reduce machining times and increase productivity.

-

Profile Gear Grinding

Samputensili profile and continuous generating grinding machines use the most advanced tooling technology to provide superior performance.

-

THE R Series Rack Grinding Machines (G Line)

With Kesel’s latest grinding machine, the R-Series G Line, large-volume gear rack profile grinding is achieved with greater speed and precision than ever before.It enables you to meet your productivity and quality goals in a short timeframe.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.