- English

- Japanese

- TEL

- 81-78-335-7573

Kesel Cross serrated flange milling machine CSF

- Overview

-

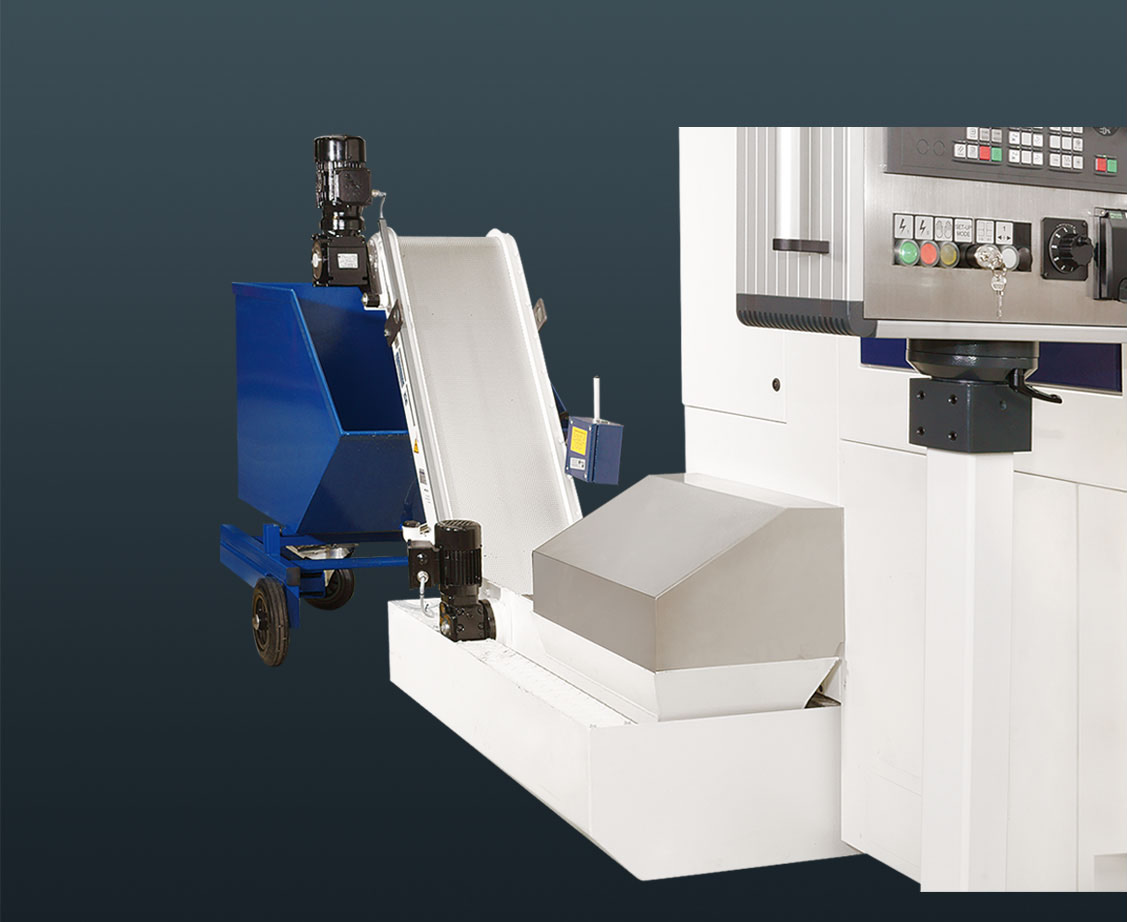

The Kesel CSF machine is especially engineered and built for tooth profile milling of cross serrated flanges and covers a wide range of customary parts. Short cycle times and highest accuracy in combination with absolute competitive production and tool cost make the CSF an outstanding machine for this specific task. It is equipped with a Siemens SINUMERIK 840D sl control as well as Siemens servo drive units. Optional features make it possible to combine this machine with different automation possibilities and to consider various product specific needs.

Options

- Milling accessories for different types of flange

- Preparation for automation

Specs

| Technical Data* | |

|---|---|

| Travel range | |

| X-axis (horizontal, table-axis) | ± 15 mm (manual) |

| Y-axis (vertical, cutting depth) | 230 mm |

| Z-axis (horizontal, milling stroke) | 370 mm |

| B-axis (positioning of the flange) | 0 - 70 ° |

| Milling head | |

| Type | F 55.4, transmission with high power drive |

| Power | 43 kW S6 40 % |

| RPM | max. 315 rpm, contionously variable |

| Milling arbor | SK 50 |

| Min. diameter of milling cutter | 128 mm + 2x cutting depth + 5 mm safety + resharpening (acc. to manufacturer) |

| Max. diameter of milling cutter | 250 mm |

| Max. milling width | 200 mm (For cutter design concepts contact Kesel) |

| Control | |

| Control | Siemens SINUMERIK 840D sl |

| Clamping system | |

| Clamping system | Hydraulic workpiece clamping system, swivel angle 70˚ |

| Coolant and swarf removal | |

| Cooling lubricant | Emulsion |

| Filling capacity | 380 litres |

| Fine filtration | Magnetic filter roller for fine filtration and oil skimmer |

| Electrical connection | |

| Voltage | 3 x 400 V |

| Amperage | 80 A |

| Dimensions and weight | |

| Installation dimensions | (L x D x H) 5,200 x 2,900 x 2,700 mm |

| Machine weight | ca. 6,700 kg |

Special Purpose Machinery

-

Kesel Bandsaw blade milling machine FS 1500

The new FS 1500 is a highly productive machine based on decades of expertise in manufacturing special purpose milling machines for milling teeth in carbon and bimetal bandsaw blades of up to 80 mm band width and within the milling range of 32 – 1.4 teeth per inch.

-

Kesel Bandsaw blade milling machine FS 2500

The FS 2500 is successor to the FS 2000. After successfully launching the FS 1500 Kesel is now introducing a new revised machine to its range of big bandsaw blade milling machines.

-

Kesel vertical / horizontal bandsaw blade coiling systems

Our horizontal and vertical coiling systems, developed in-house, interface with our bandsaw blade milling machines to create complete systems for the fully automatic feed-through milling of up to 40 bands.

-

Kesel Band setting machine TSM 160s

The design of the Kesel TSM 160s is based on our many years of experience in building machines for the bandsaw blade production.

-

Kesel Cross serrated flange milling machine CSF

The Kesel CSF machine is especially engineered and built for tooth profile milling of cross serrated flanges and covers a wide range of customary parts.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.