What is a gear shaving machine?

2021.03.30 cutting tools、machine

Gear shaving machine is a solution used in the finishing operation of an external spur and helicalgear. It is also possible to shave an internal gear, although generally the work conditions are less favorable. The shaving process can improve the quality and precision of a hobbed gear of 3 classes. However, the final results depend not only on the accuracywith which the shaving cutter and the gear shaving machine is designed and manufactured, but also on the quality achieved with the prior machining.

Gear shaving is still today the most widely used method for the finishing of gear teeth, especially for the continuous production of large lots, since it represents the best cost/performance ratio. The main limit of the gear shaving process is the lack of the chance to remove the distortion caused by heat treatment. Usually, when high noiselessness and strict quality levels are strictly required, the grinding operation is the best solution, although obviously more expensive.

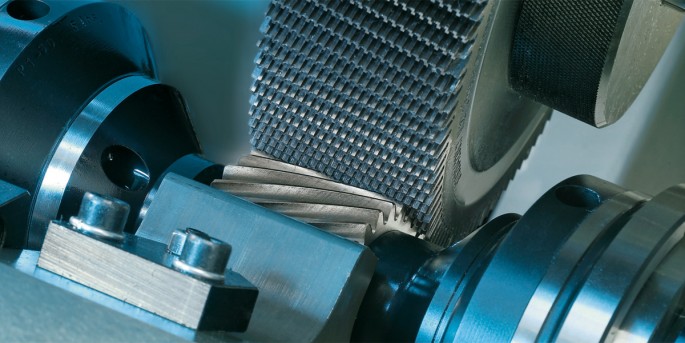

In the automotive industry, the vast majority of gears used in gearboxes are suitable for gear shaving. The productivity of a gear shaving machine is much higher compared to a gear grinding machine. The gear shaving operation is composed by the simultaneous rotation ofworkpiece and cutter as a pair of gears with crossed axes. The crossed axes generate a reciprocal sliding action between the flank, gear tooth and the cutter teeth.

Gear shaving should be carried out using extremely precise gear shaving machines and tools. That is why it is essential to rely on companies with broad and proven understanding of gear technology with a particular focus on innovation and development, so that they can offer the best cost effective solution on the market for your specific needs.

Samputensili Machine Tools has an excellent reputation in the gear shaving machine industry thanks to its brand SICMAT. The SICMAT product range includes the famous RASO 200, RASO 400 and RASO 600. They are all synonymous of quality, excellent performanceand high reliability since the ‘80s.

SEIBU SHOKO CO., LTD.

SEIBU SHOKO CO., LTD.